Key Findings

- Most roles are mid-level: 67% of process engineering positions target professionals with 5+ years of experience

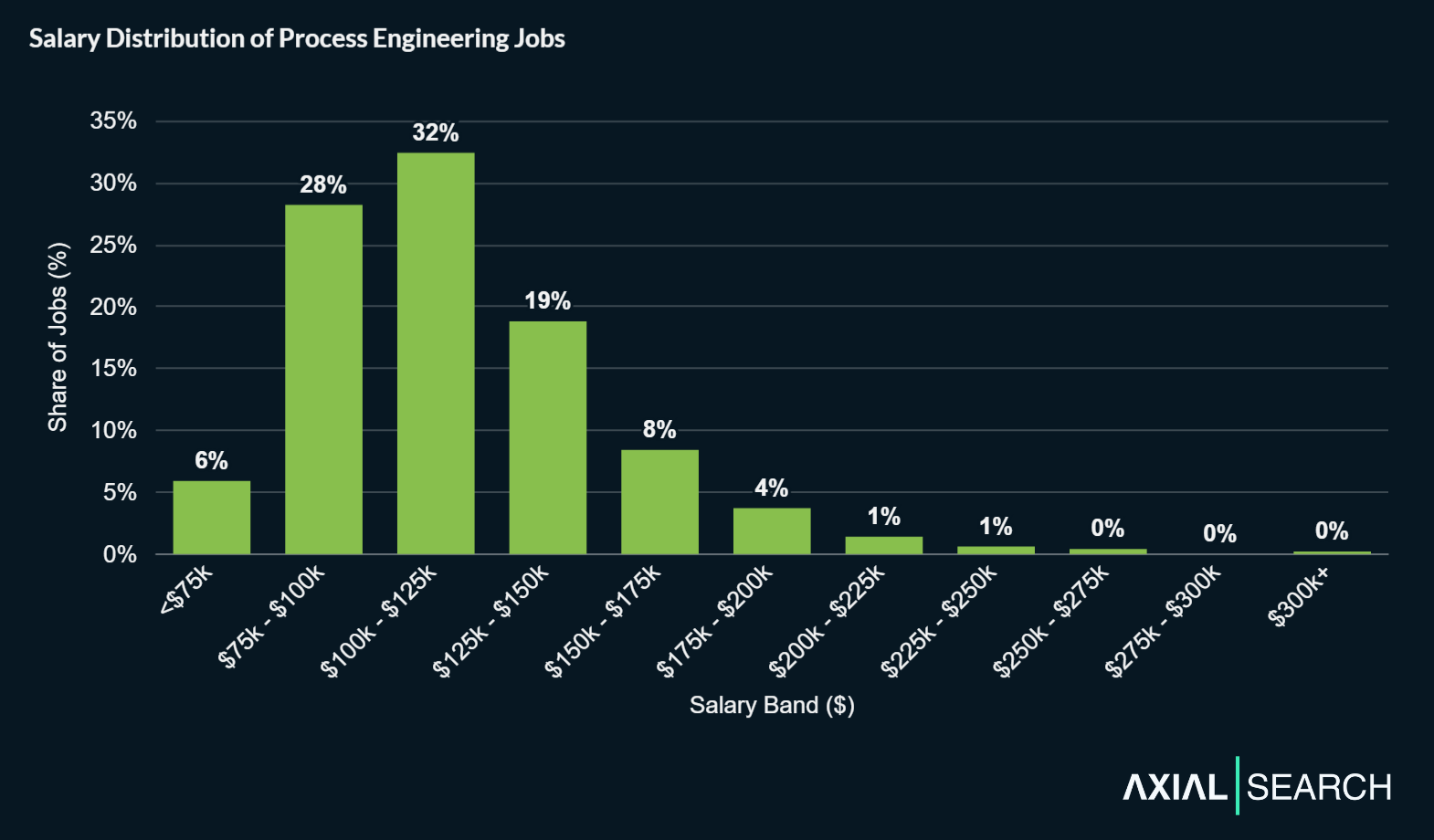

- Median salary is $111,500: The middle 80% of roles pay between $80K and $163K annually

- Certifications appear in 22% of posts: Professional Engineer (PE), Lean Six Sigma Black Belt and Six Sigma Green Belt lead requests

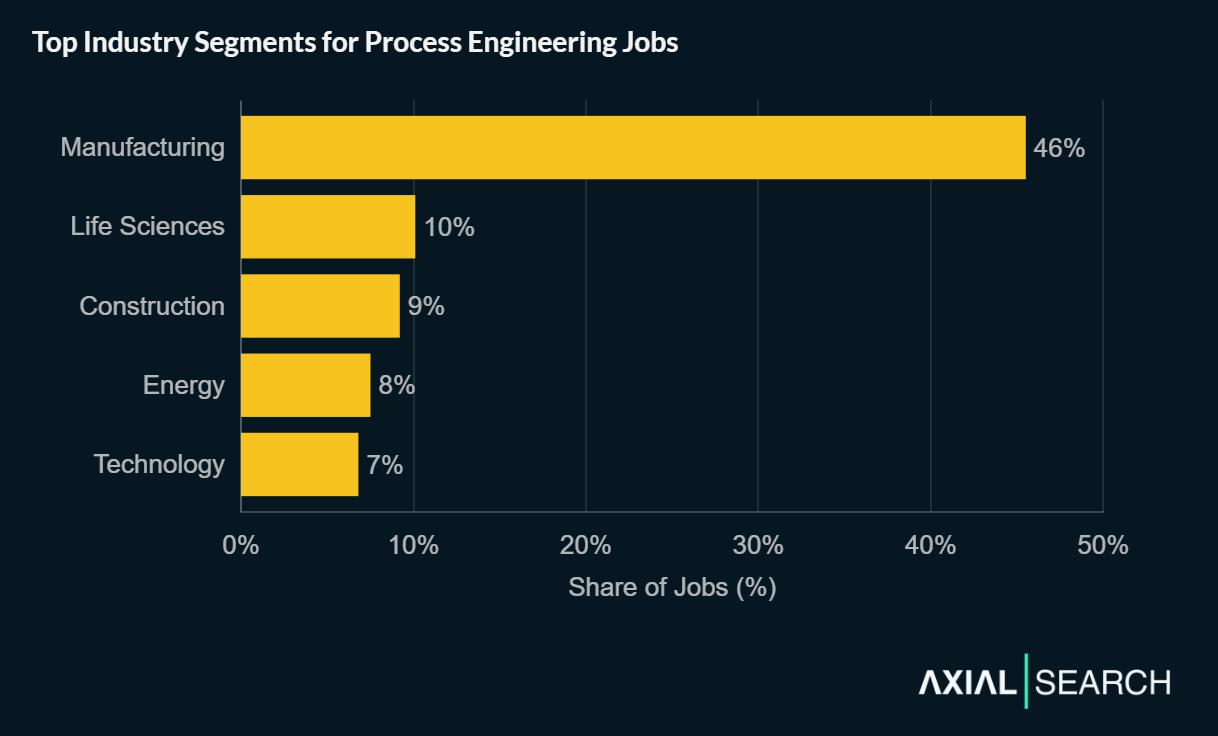

- Manufacturing firms dominate hiring: Manufacturing (46%), Life Sciences (10%) and Construction (9%) lead postings

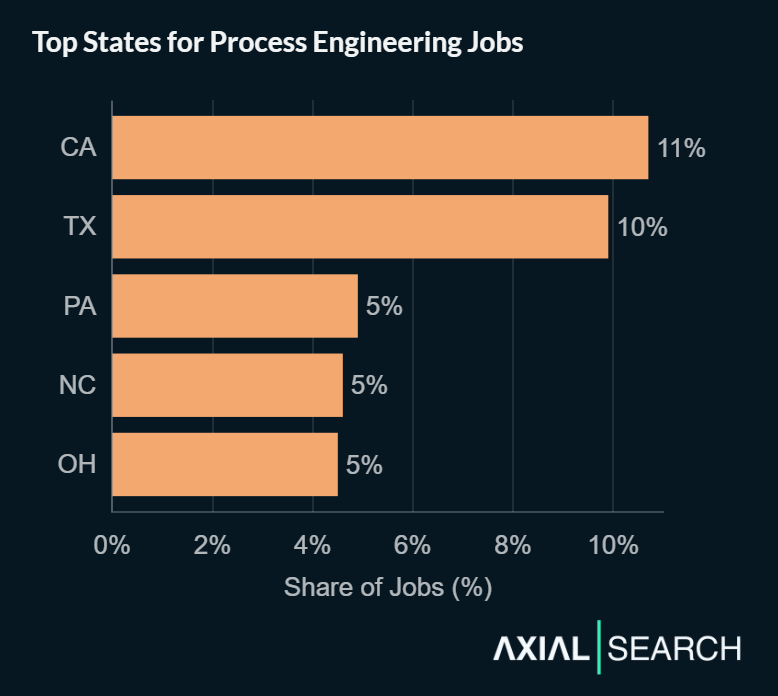

- California and Texas lead the market: CA captures 11% of U.S. roles, TX captures 10%

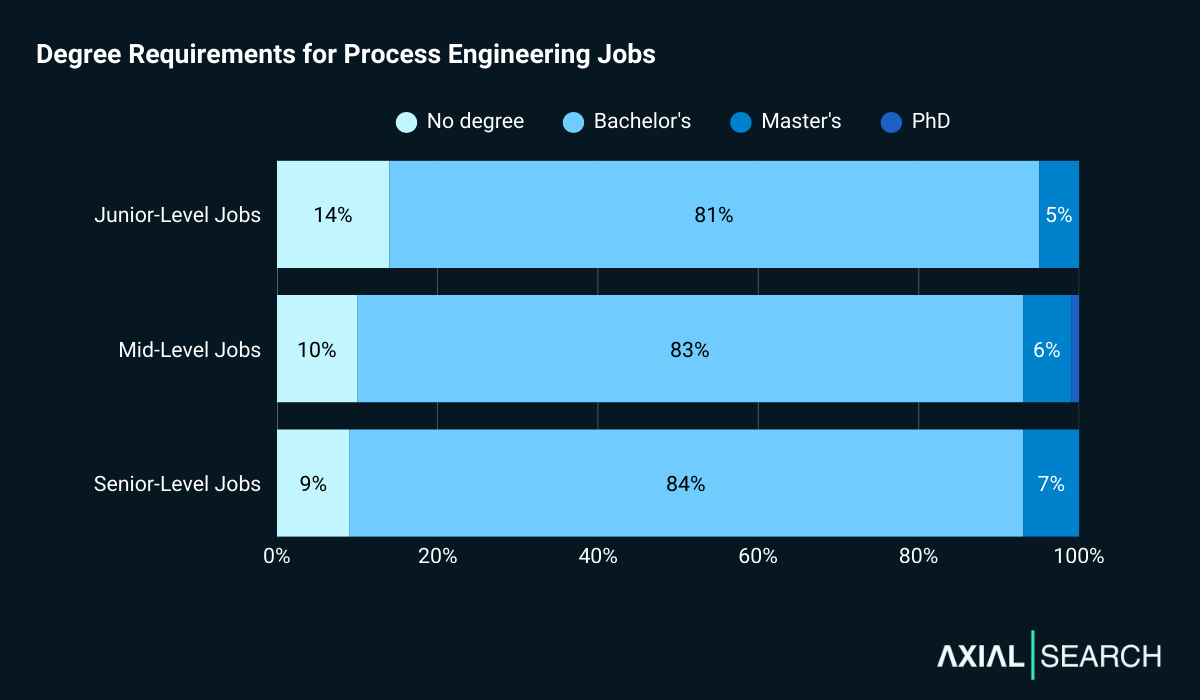

- Degrees strongly required: Only 14% of junior roles skip degree requirements, dropping to 9% at senior levels

The Role of a Process Engineering Professional

The market dynamics here reflect broader patterns we see across process optimization recruitment, where organizations invest in professionals who can drive measurable operational improvements through technical expertise and systematic problem-solving.

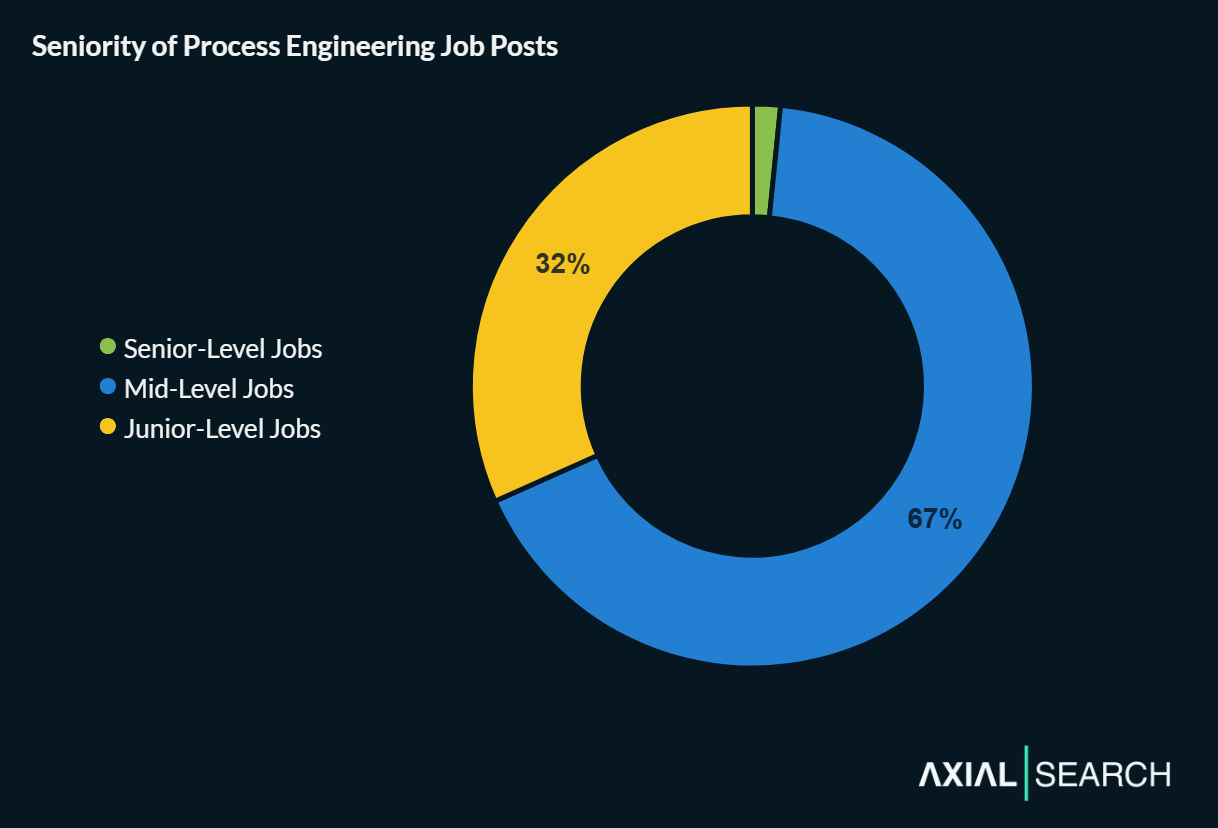

We categorized each role by seniority and found the market heavily favors mid-level professionals – they account for two-thirds of all postings.

We then extracted experience requirements (87% of roles mentioned a specific number) and calculated the average minimum at each level of seniority. Finally, we analyzed job titles to identify the most common naming conventions at each level.

- Junior (32% of roles)

- Minimum experience: 2 years

- Common titles: Process Engineer, Chemical Process Engineer, Process Engineering Technician

- Mid-Level (67% of roles)

- Minimum experience: 5 years

- Common titles: Senior Process Engineer, Process Improvement Engineer, Business Process Engineer

- Senior (1% of roles)

- Minimum experience: 10 years

- Common titles: Director of Process Engineering, Process Engineering Manager, Principal Process Engineer

Two-thirds of process engineering jobs target mid-level professionals

What Do Process Engineering Jobs Involve?

So what is a process engineer actually responsible for day-to-day? We analyzed the language across all 6,210 job posts to extract the core responsibilities at each level. What emerged is a clear progression of expectations from hands-on execution to organizational leadership:

Junior-Level Roles:

- Design and optimize processes while troubleshooting production issues

- Execute process validation projects and develop technical documentation

- Conduct data analysis identifying variation sources and implementing continuous improvement methodologies

Mid-Level Roles:

- Own end-to-end process and equipment performance for production lines

- Develop scalable manufacturing strategies balancing cost, quality and throughput

- Provide technical authority for process safety and regulatory compliance

Senior-Level Roles:

- Define manufacturing engineering strategy building organizational capabilities

- Lead commercialization roadmaps and capital investment decisions

- Develop technical talent and standardize best practices across multi-site networks

Key takeaway: Junior engineers optimize existing processes, mid-level leaders own production systems end-to-end, senior executives define manufacturing strategy. Each step up means less troubleshooting and more strategic influence over how operations scale.

Who’s Hiring for Process Engineering?

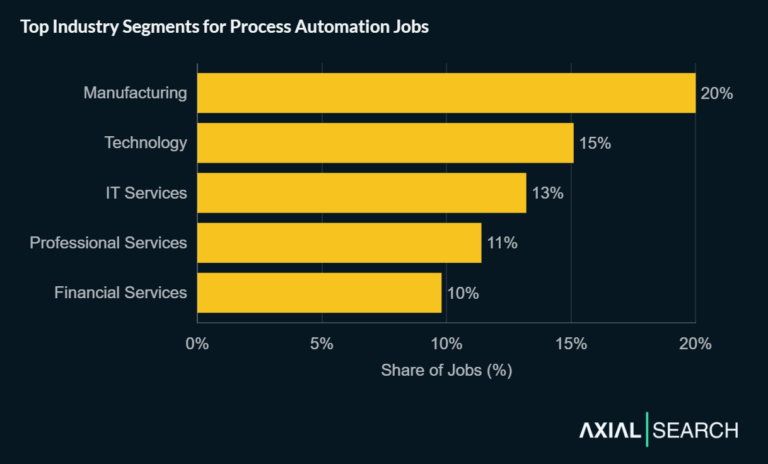

Manufacturing leads with 46% of process engineering postings – no surprise given the discipline’s roots in production optimization. Life Sciences follows at 10%, with Construction rounding out the top three at 9%. Energy captures 8%, and Technology at 7% completes the top five.

The manufacturing concentration makes sense – physical production creates the greatest demand for workflow optimization, where hands-on process improvements and equipment troubleshooting generate immediate value.

Manufacturing accounts for nearly half of process engineering openings

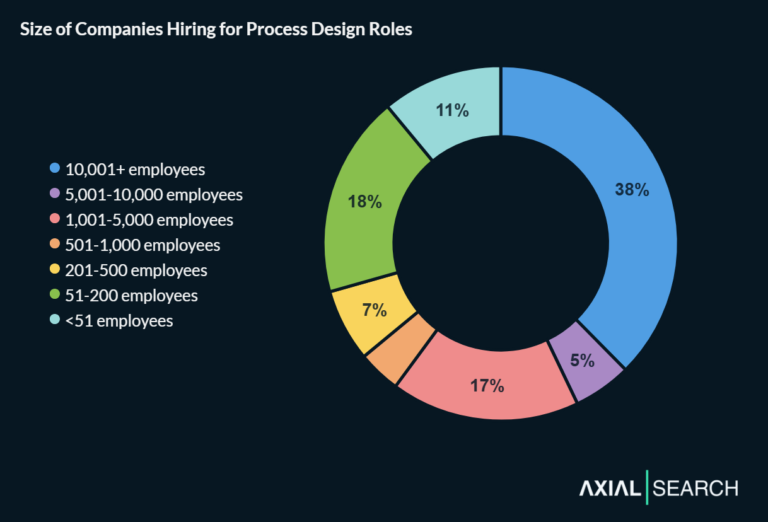

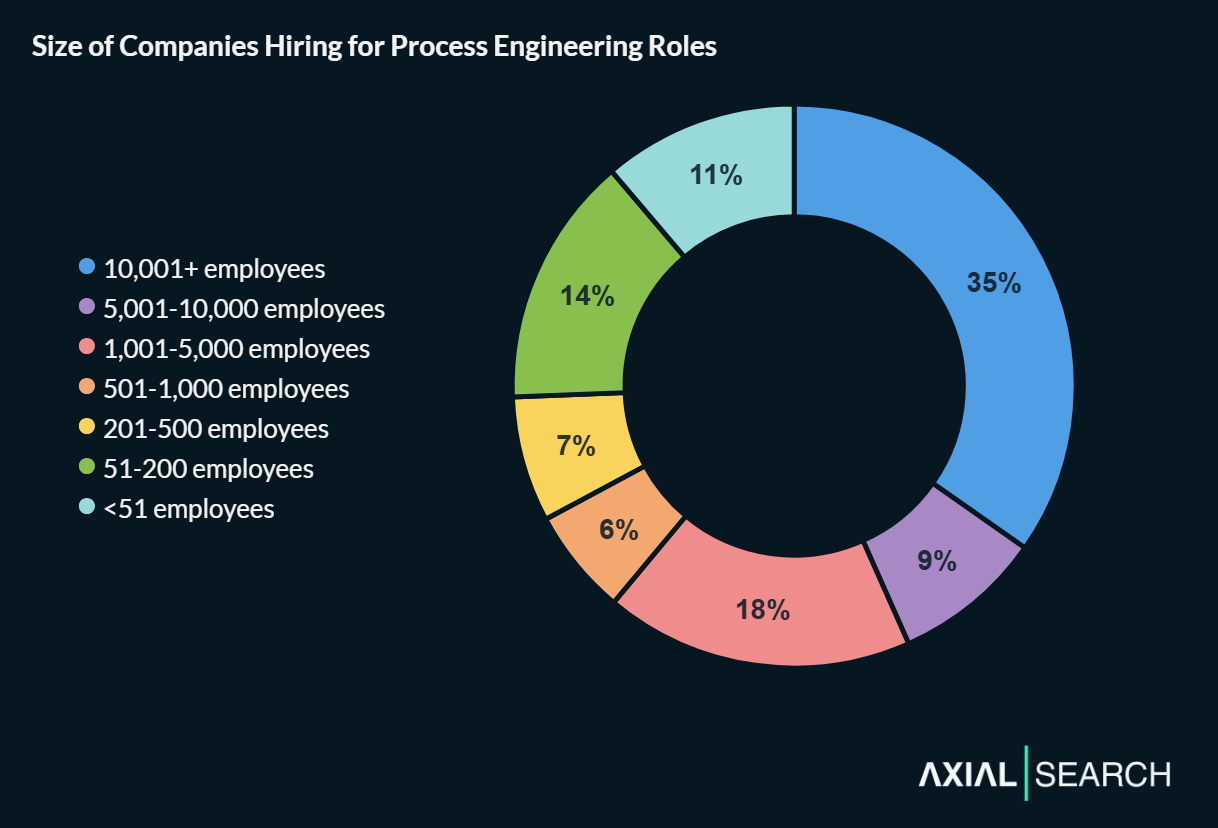

Large companies with 10,001+ employees account for 35% of postings – modestly above the economy’s broader ~30% workforce distribution across the U.S. economy. Organizations with 1,001-5,000 employees add another 18%, meaning roughly half of process engineering roles are at companies with over 1,000 employees.

What’s striking is the distribution across company sizes – small businesses (fewer than 51 employees) still capture 11% of roles, while mid-sized companies (51-500 employees) post another 21%. This broad spread suggests process engineering serves organizations at multiple scales, from massive plants requiring formalized operating systems to smaller manufacturers building production capabilities from the ground up.

Process engineers are needed by companies of all sizes

Where Are Process Engineering Jobs Located?

Manufacturing hubs lead process engineering hiring

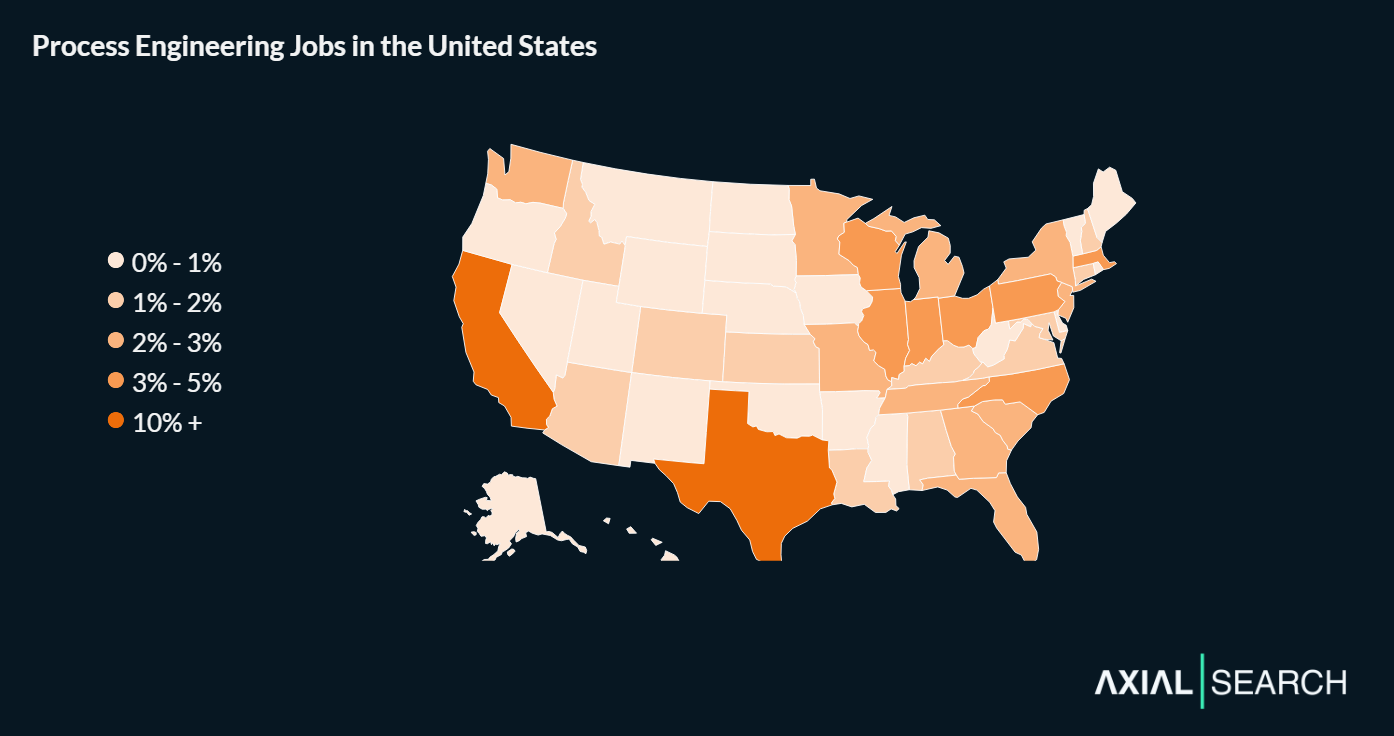

California leads with 11% of all process engineering postings. Texas follows closely at 10%, while Pennsylvania, North Carolina, Michigan and Ohio each capture 5% of the market.

The concentration in these states reflects where advanced manufacturing and life sciences operations cluster. Remote roles account for just 2% of postings – the hands-on nature of shop floor work requires physical presence for equipment troubleshooting and process validation.

States worth watching include Wisconsin, Indiana, Illinois and Georgia – each capturing roughly 3-4% of the market and representing established manufacturing regions with ongoing modernization needs.

Process engineering is a hands-on role – only 2% of positions are remote

Key takeaway: California and Texas essentially tie at the top with 11% and 10% of opportunities respectively. The near-elimination of remote work (2%) reflects how this discipline requires substantial on-site presence for production environment engagement and hands-on problem-solving.

Requirements for Process Engineering Jobs

We analyzed the minimum requirements of each job post and found that most process engineering jobs (88%) require some form of degree. The pattern remains remarkably consistent across all seniority levels.

For junior roles, 86% require a degree (81% bachelor’s, 5% master’s). The remaining 14% don’t specify formal education requirements.

Mid-level positions show nearly identical patterns: 90% require a degree (83% bachelor’s, 6% master’s, 1% PhD).

Senior roles maintain strict requirements: 91% require a degree (84% bachelor’s, 7% master’s).

Degree fields of study that are typically requested of process engineers include:

- Chemical Engineering (42%)

- Mechanical Engineering (31%)

- Engineering (24%)

- Electrical Engineering (11%)

- Industrial Engineering (9%)

- Manufacturing Engineering (8%)

- Chemistry (5%)

- Materials Science (5%)

- Civil Engineering (3%)

- Environmental Engineering (3%)

Degree requirements stay consistent across experience levels

Requested Qualifications in Process Engineering Job Posts

Process engineers must excel at communication, problem-solving and troubleshooting. Communication appeared in 32% of listings, problem-solving in 29%, and troubleshooting in 23% – reflecting the role’s dual nature as both technical problem-solver and cross-functional collaborator.

Project management (23%), process optimization (21%) and data analysis (21%) round out the core capabilities, emphasizing the need to manage structured improvement initiatives while translating data insights into operational changes.

Deep methodological expertise matters equally. Six Sigma, Lean Manufacturing and Statistical Process Control are table stakes, supported by hands-on experience with frameworks like Design of Experiments (DOE), FMEA and Process Safety Management.

Just 22% of postings request specific certifications, but when they do, these credentials lead:

- Professional Engineer (PE)

- Lean Six Sigma Black Belt

- Six Sigma Green Belt

- Project Management Professional (PMP)

- Engineer in Training (EIT) / Fundamentals of Engineering (FE)

- Certified Safety Professional (CSP)

- PROSCI Change Management

- CISSP

Key takeaway: Technical depth in Six Sigma and statistical methods is table stakes, but change management skills like communication and cross-functional collaboration separate strong candidates from purely technical ones. As seniority increases, regulatory compliance knowledge and team leadership become equally critical to process expertise.

What do Process Engineering Jobs Pay?

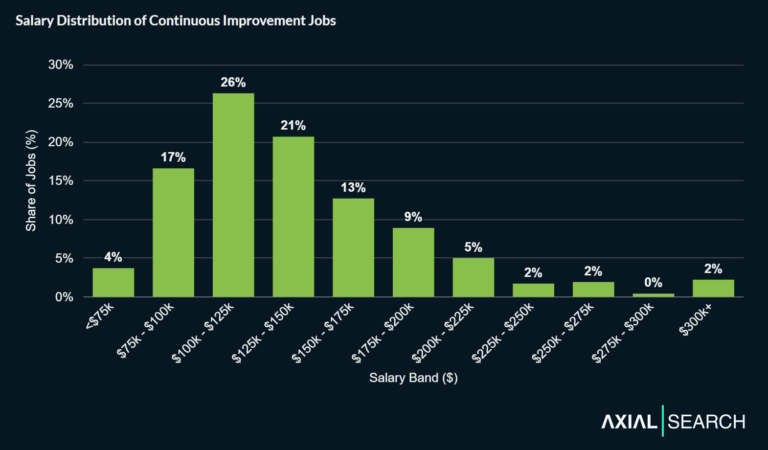

Just under half (46%) of the process engineering roles we analyzed included an advertised salary.

There was significant breadth in the ranges employers posted, so we normalized the data by selecting the midpoint for our analysis. From our experience, this is generally a much more indicative number for an employer’s target offer – especially in the current market where initial ranges often run wide.

Across the entire dataset of salaries, we found the median salary for process engineering positions to be $111,500. The middle 80% of salaries (10th to 90th percentile) ranged from $80,000 to $162,500.

Most process engineering salaries fall between $80K and $163K

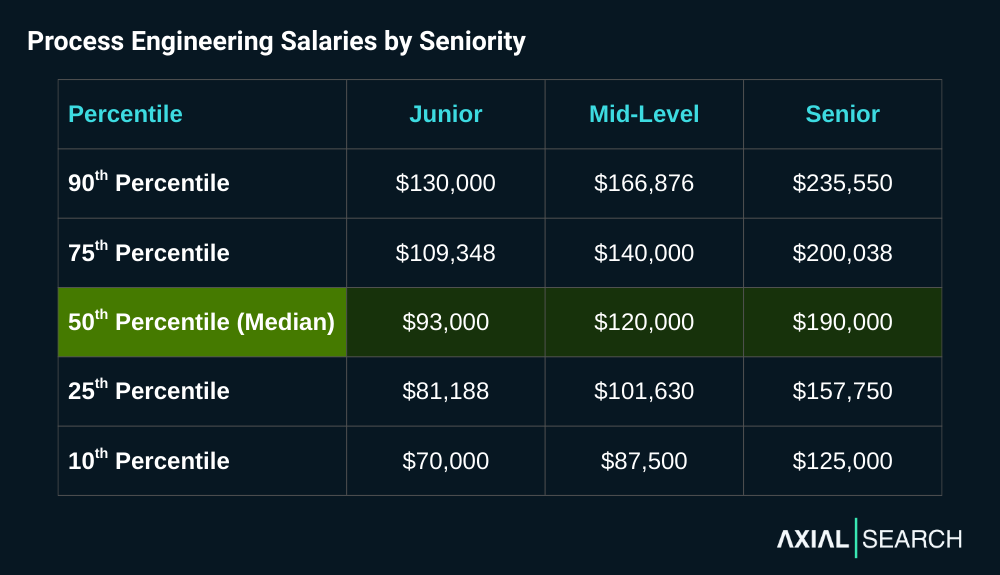

Breaking process engineering salaries down by seniority reveals substantial progression with notable overlap between tiers. Junior roles start at a median $93,000, with mid-level positions climbing 29% to $120,000. The real premium appears at senior levels – a 58% jump to $190,000 median.

What’s notable is the range overlap: junior salaries at the 90th percentile ($130,000) approach mid-level positions at the 75th percentile ($140,400). This compression reflects how specialized expertise – particularly in bioprocess, semiconductor or advanced materials – can command premium compensation even at earlier career stages.

Senior roles show the widest absolute range – $125,000 to $240,500 – indicating significant variation based on industry sector, facility complexity and leadership scope. Life sciences positions typically command the highest premiums given specialized bioprocess and pharmaceutical expertise.

Senior process engineers earn 58% more than mid-level professionals

Key takeaway: Process engineering positions pay exceptionally well at senior levels. The median senior-level salary of $190,000 puts these roles in the top 7% of all earners in the United States. Mid-level professionals earning the median $120,000 land in the top 17%.

Final Thoughts

For Candidates: Pursue Professional Engineer (PE) licensure and Lean Six Sigma certifications early – these credentials validate technical competence while opening leadership opportunities. Build hands-on experience with statistical methods and DOE, as data-driven problem-solving separates strong candidates. For mid-level roles, demonstrating you’ve owned production systems end-to-end with measurable improvements (cost, quality, throughput) matters most. At senior levels, experience defining manufacturing strategy and building technical capabilities across sites commands the premium.

For Employers: The tight salary clustering around $120,000 for mid-level roles reflects market maturity – fall significantly below that and expect longer time-to-fill. The strongest signal for senior candidates is experience scaling production systems across multiple facilities and building organizational capabilities, not just optimizing individual processes. Remote flexibility is essentially non-existent (2%) given the hands-on nature of this work – expect on-site requirements for nearly all roles.

Methodology

We analyzed 6,210 process engineering job postings collected from LinkedIn, Indeed and Glassdoor between November 2024 and January 2025. The dataset was limited to full-time roles posted in the United States that explicitly mentioned “process engineering,” “process engineer” or close variations in the job title.

Duplicate postings were removed using job title, company name and location matching. Seniority levels were determined by analyzing job titles alongside minimum experience requirements stated in each posting. When experience ranges were provided, the lower bound was used for consistency.

Salary data was extracted from the 46% of postings that included compensation ranges. We used the midpoint of each range for analysis, as this most closely reflects employer target offers in practice.

Industry classifications were assigned based on company descriptions and verified against LinkedIn company data where available. Geographic analysis was conducted at the state level using the primary job location listed in each posting.