The business impact of six sigma jobs

Six sigma jobs deliver quantifiable improvements in process performance, quality and efficiency. These process optimization practitioners measure impact through specific metrics that demonstrate reduced variation and improved capability.

Organizations waste 15–20% of sales revenue on poor quality. In some cases, cost of poor quality reaches 40%, draining profits through rework, defects, delays and customer dissatisfaction. Lean Six Sigma professionals attack this waste systematically, eliminating variation and improving processes to recover margins and strengthen operations.

The impact is substantial. U.S. EPA Lean Government initiatives cut process times by over 50% while reducing backlogs and improving service quality in areas like environmental permitting. Manufacturing Extension Partnership (MEP) client manufacturers applying Lean and Six Sigma reported $6.8 billion in cost savings, $35.8 billion in new and retained sales, and 116,700 jobs created or retained in FY2023 alone.

Takeaway: Six sigma jobs deliver measurable business impact through quantified improvements in process capability, defect rates, cycle times, and equipment effectiveness that directly improve margins and customer satisfaction.

What responsibilities define six sigma jobs?

Six sigma careers center on systematic process improvement through structured problem-solving methodologies. Practitioners work across industries to reduce variation, eliminate waste and improve quality.

Core responsibilities include:

- DMAIC project execution: Plan and execute Define-Measure-Analyze-Improve-Control cycles to reduce variation and improve process performance through structured problem-solving.

- Project charter development: Develop and maintain a project charter that clarifies problem statements, goals, scope, timeline, metrics and team roles to align stakeholders.

- Voice of customer translation: Capture customer needs through methods like interviews and surveys and translate them into critical-to-quality requirements to guide improvements.

- Measurement system analysis: Assess measurement system accuracy, precision and stability (such as Gage R&R) to ensure data quality before analysis and decision-making.

- Process capability assessment: Calculate capability indices like Cp and Cpk to evaluate whether processes can meet specifications and identify improvement needs.

- Root cause analysis: Use cause-and-effect (Ishikawa) diagrams and related methods to systematically identify and prioritize potential root causes.

- Failure mode analysis: Conduct Failure Mode and Effects Analysis to identify potential failure modes, evaluate risk, prioritize actions and prevent issues before they occur.

- Value-stream mapping: Use value-stream mapping to analyze current material and information flows, identify waste and design a leaner future state.

- Kaizen facilitation: Plan and run kaizen activities to engage teams in rapid, incremental improvements to processes.

- Control planning: Create control plans that define key controls, monitoring methods, responsibilities and reaction plans to hold the gains after improvement.

- Statistical process control: Deploy control charts to monitor process behavior, distinguish common versus special cause variation and trigger corrective actions.

- Standard work documentation: Create and maintain standardized work to capture the current best method, stabilize processes and provide a baseline for continuous improvement.

Takeaway: Six sigma responsibilities focus on structured problem-solving through DMAIC methodology, statistical analysis, waste elimination and control system implementation to drive sustainable process improvements.

How are lean six sigma roles positioned within organizations?

Lean six sigma jobs operate within a tiered belt system that defines roles, responsibilities and organizational reporting structures. This hierarchy enables effective deployment across enterprises.

Six Sigma programs are organized with executive sponsors and Champions who set direction and remove barriers. Master Black Belts mentor and govern methodology application. Black Belts lead projects full-time. Green Belts support improvement efforts alongside their regular duties. This deployment typically sits under senior leadership and operates cross-functionally.

ASQ describes Black Belts as professionals who lead improvement projects and understand team dynamics and facilitation. The emphasis is on leadership of cross-functional teams rather than line management authority, with Black Belts influencing through expertise and project results.

Deloitte recommends a centralized transformation office as the nerve center that coordinates initiatives, tracks value and builds capabilities across functions. This structure serves as a typical home for Lean Six Sigma roles, providing governance and methodology oversight.

NIST MEP explains Lean engages employees at all levels and uses cross-functional teams across operations, engineering, quality and supply chain to remove waste and improve flow. This broad engagement model means six sigma professionals collaborate widely rather than operating in silos.

Takeaway: Six sigma roles function within a belt hierarchy under executive sponsorship, typically housed in transformation offices or quality functions with strong cross-functional collaboration across operations, engineering and supply chain teams.

Essential skills for lean six sigma careers

Lean six sigma careers demand a distinctive blend of statistical expertise, process analysis capabilities and leadership competencies. Mastering these skills enables practitioners to drive measurable improvements across diverse business contexts.

Foundational statistical and analytical skills include:

- Statistical analysis proficiency: Proficiency in descriptive statistics, probability distributions, confidence intervals, hypothesis tests (t-tests, ANOVA, chi-square), correlation and regression—core to reducing variation and validating improvements.

- Process capability analysis: Capability indices (Cp, Cpk, Pp, Ppk) quantify how well a process meets specifications. NIST provides guidance on assumptions, calculation and interpretation.

- Measurement system evaluation: Reliable data requires assessing measurement variation. Gage R&R studies quantify repeatability and reproducibility, a standard Six Sigma competency.

- Statistical process control: SPC uses control charts to distinguish common versus special-cause variation and sustain gains. NIST details chart selection (X̄-R, individuals, p, c) and interpretation.

Process improvement and problem-solving capabilities:

- DMAIC methodology: Define-Measure-Analyze-Improve-Control is the foundational Six Sigma framework. The Black Belt Body of Knowledge is organized by DMAIC and includes project chartering, VOC/CTQ definition, process mapping, data collection, solution development and control planning.

- Value-stream mapping: VSM is a core Lean technique to visualize material and information flow, identify waste and design a future state with improved lead time and value flow.

- Root cause methodology: Cause-and-effect (fishbone) diagrams help teams structure potential causes, often combined with 5 Whys to drill down to root causes before the Improve phase.

- Risk analysis: FMEA proactively prioritizes risks by severity, occurrence and detection to prevent defects and build robust controls—common in Measure, Analyze and Improve phases.

Leadership and collaboration competencies:

- Team leadership: The Black Belt Body of Knowledge emphasizes leading teams, facilitation and team dynamics to drive cross-functional problem-solving and sustain improvements.

- Stakeholder management: Green Belt Body of Knowledge includes stakeholder analysis, communication planning and presenting results—critical for alignment, adoption and tollgate success.

Takeaway: Success in lean six sigma careers requires mastering statistical methods, process analysis tools, and team leadership capabilities to drive cross-functional improvements and sustain results.

What frameworks guide lean six sigma professionals?

Six sigma professionals leverage multiple frameworks and methodologies to diagnose problems, analyze root causes and implement sustainable improvements. Mastering these tools enables practitioners to select the right approach for each situation.

Core Six Sigma and Lean frameworks include:

- DMAIC: Core Six Sigma method to reduce variation and improve processes by defining the problem, measuring baseline performance, analyzing root causes, improving the process and controlling to sustain gains.

- Value-Stream Mapping: Visual method to map material and information flow, identify waste and design a future-state process with improved flow and lead time.

- Just-in-Time: Producing only what is needed, when needed, in the amount needed. Emphasizes takt time, continuous flow and pull to eliminate waste.

- 5S: Structured approach (Sort, Set in order, Shine, Standardize, Sustain) to create clean, organized and visual workplaces that enable flow and quality.

- Kaizen Events: Focused, short-duration improvement events that engage cross-functional teams to rapidly analyze and improve targeted processes.

Analytical and problem-solving tools:

- SIPOC: High-level process mapping tool used early in projects to clarify scope, boundaries, key inputs/outputs and customer requirements.

- 5 Whys: Simple iterative questioning technique to trace symptoms to underlying root causes before implementing corrective actions.

- FMEA: Systematic risk analysis to identify failure modes, assess effects and causes, prioritize by risk and implement preventive controls.

- Design of Experiments: Structured experimental approach to identify key factors, optimize settings and quantify cause–effect relationships efficiently.

- Statistical Process Control: Monitoring process behavior with control charts to distinguish common versus special cause variation and maintain stable, capable processes.

Advanced Lean principles:

- Jidoka: Principle of autonomation—stop the process when an abnormality occurs and separate people from machines so issues are fixed at the source.

- Poka-Yoke: Designing processes or devices to prevent errors or make them immediately detectable, reducing defects at the source.

Takeaway: Proficiency across multiple frameworks from foundational DMAIC and VSM to specialized tools like DOE and Jidoka enables practitioners to diagnose process challenges accurately and design targeted interventions for sustainable improvement.

Which software tools do lean careers depend on?

Lean six sigma professionals leverage specialized software platforms to analyze data, conduct experiments, monitor processes and simulate improvements. These tools accelerate projects and increase analytical rigor.

Statistical analysis and quality management platforms:

- Minitab Statistical Software: Provides control charts, capability analysis, regression, DOE and Gage R&R used across DMAIC projects.

- InfinityQS: Provides real-time SPC (Enact/ProFicient), process capability, alarms and manufacturing quality dashboards.

- GAGEpack: Manages gage calibration and executes MSA studies including Gage R&R, bias and linearity to ensure measurement quality.

Experimental design and optimization tools:

- Design-Expert: Supports factorial, response surface, mixture designs, optimization and analysis essential to Improve-phase experimentation.

Risk analysis and FMEA platforms:

- APIS IQ-Software: Supports structured DFMEA/PFMEA authoring, linkages and action tracking aligned with AIAG/VDA practices.

Process analysis and simulation software:

- Celonis: Analyzes system event logs to reveal bottlenecks, rework, throughput issues and cycle-time waste for targeted improvements.

- SIMUL8: Provides fast discrete-event simulation for analyzing throughput, WIP, staffing and scheduling scenarios.

Takeaway: Effective six sigma practice requires proficiency across statistical analysis platforms like Minitab, real-time SPC systems, DOE software, and process mining tools to execute rigorous DMAIC projects and sustain control.

Recognized qualifications for lean six sigma jobs

Lean six sigma jobs typically require bachelor’s degrees in engineering, business, operations management or related technical fields. Educational backgrounds vary, but analytical and process-focused disciplines provide strong foundations.

Quality engineers—frequent Lean Six Sigma practitioners—typically have a bachelor’s degree in engineering or a related field. This technical education provides the statistical and analytical foundation necessary for process improvement work.

Industrial engineers, who commonly practice Lean Six Sigma, typically enter with a bachelor’s degree. Industrial engineering curricula emphasize process optimization, statistical methods and systems thinking that align directly with six sigma methodologies.

Professional experience often matters as much as formal education. Employers value demonstrated experience leading continuous improvement projects, applying statistical methods and working cross-functionally. Many successful practitioners enter through operations, quality, engineering or project management roles before specializing in Lean Six Sigma.

Industry-specific knowledge can be advantageous. Healthcare organizations value understanding of clinical workflows and regulatory requirements. Manufacturing environments prefer candidates with production experience. Financial services seeks practitioners familiar with process controls and risk management.

Advanced degrees in business administration, industrial engineering or quality management can accelerate career progression. However, professional certifications and project results typically carry more weight than additional degrees for advancement.

Takeaway: Lean six sigma careers typically require bachelor’s degrees in engineering or related technical fields, with professional experience and demonstrated project results often valued more highly than advanced degrees.

Which certifications advance a six sigma career?

Professional certifications demonstrate mastery of six sigma methodologies and validate practical experience. Several organizations offer respected credentials that enhance career prospects and earning potential.

Core Six Sigma certifications by belt level:

- Certified Six Sigma Yellow Belt: Entry-level Six Sigma credential validating understanding of fundamental Six Sigma concepts and supporting roles on process improvement teams.

- Certified Six Sigma Green Belt: Recognizes professionals who analyze and solve quality problems and support or lead process-improvement projects using Six Sigma methods.

- Certified Six Sigma Black Belt: Validates mastery of Six Sigma philosophies and principles, team leadership and advanced analytical tools to reduce variation and improve quality.

- Certified Six Sigma Master Black Belt: Expert-level credential for leaders who mentor Black and Green Belts and align Lean Six Sigma initiatives with organizational strategy.

Lean-focused certifications:

- SME Lean Certification: Industry-developed, experience-based program that validates lean knowledge and application at increasing levels—from tactical (Bronze) to enterprise leadership (Gold).

Complementary quality and project management credentials:

- Certified Quality Engineer: Certifies competence in principles of product and service quality evaluation and control, including measurement, analysis and improvement techniques used in Lean Six Sigma.

- Project Management Professional: Demonstrates proven project leadership experience and ability to deliver projects across predictive, agile and hybrid approaches—valuable for leading Lean Six Sigma initiatives.

- ISO 9001 Lead Auditor: Develops competence to plan, conduct and report first-, second- and third-party audits of quality management systems to ISO 9001—complements Lean Six Sigma in maintaining process control.

Takeaway: Professional certifications from Yellow Belt through Master Black Belt provide structured career progression, with ASQ and SME offering the most widely recognized credentials supplemented by quality engineering and project management certifications.

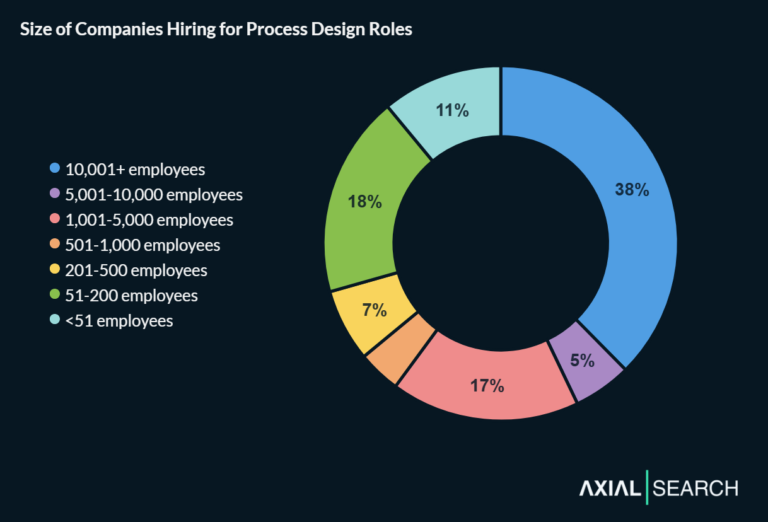

Career growth in lean six sigma jobs

Lean six sigma careers offer clear progression paths with increasing responsibility, complexity and compensation. Advancement typically follows the belt system with opportunities to specialize or transition into leadership roles.

Typical six sigma career progression:

- Yellow Belt/Team Member: Supporting improvement projects and participating in problem-solving activities

- Green Belt: Leading smaller projects while maintaining regular job responsibilities

- Black Belt: Full-time improvement project leadership and team facilitation

- Master Black Belt: Mentoring Black and Green Belts and aligning initiatives with strategy

- Director of Continuous Improvement: Leading enterprise transformation and building organizational capability

Entry routes vary by background. ASQ explains Green Belts are employees who implement Six Sigma alongside their regular jobs under Black Belt guidance, while Black Belts devote 100% of their time to improvement. Many professionals enter by training as a Green Belt in their current role, then advance to full-time Black Belt positions.

Certification requirements reflect increasing experience. ASQ’s Certified Six Sigma Green Belt requires at least three years of work experience in areas of the Green Belt Body of Knowledge, showing a common route is gaining experience in operations or quality roles before formal certification.

ASQ’s Certified Six Sigma Black Belt requires completion of two projects with signed affidavits (or one project plus three years of experience), reflecting progression to leading improvement projects with measurable business impact.

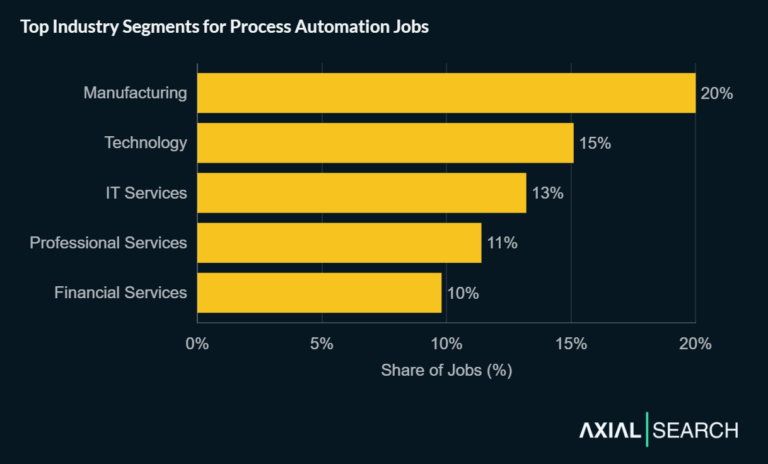

Job opportunities are increasing. Industrial engineers—a common home for Lean Six Sigma—are projected to grow 12% from 2022–2032 and are heavily employed in manufacturing and professional, scientific and technical services.

Healthcare represents significant growth potential. The Joint Commission’s Robust Process Improvement program uses Lean Six Sigma to improve safety and quality in hospitals and health systems, reflecting broad healthcare demand for these skills.

Takeaway: Six sigma careers offer structured progression from Green Belt part-time roles through Black Belt project leadership to Master Black Belt and director positions, with strong growth projected across manufacturing, healthcare, and professional services.

What associations support six sigma careers?

Professional associations provide essential networking, education and credibility that accelerate lean six sigma careers. Active participation connects practitioners with peers, resources and advancement opportunities.

Primary Six Sigma and quality associations:

- American Society for Quality: Professional association for quality practitioners. Provides Six Sigma certifications (Yellow, Green, Black Belt), membership and resources relevant to Lean and Six Sigma.

- International Society of Six Sigma Professionals: Membership organization dedicated to Six Sigma and process improvement. Provides practitioner resources, community and learning opportunities.

Lean-focused organizations:

- Lean Enterprise Institute: Nonprofit dedicated to advancing Lean thinking. Offers education, research and community for professionals applying Lean methods to reduce waste and improve quality.

- Shingo Institute: Organization promoting the Shingo Model for operational excellence. Offers education, recognition (Shingo Prize) and a community for Lean leaders.

- Association for Manufacturing Excellence: Professional association focused on enterprise excellence and Lean. Provides conferences, peer networking and resources for continuous improvement leaders.

Cross-industry improvement organizations:

- American Productivity & Quality Center: Nonprofit benchmarking and best practices organization. Provides process improvement, Lean Six Sigma and quality resources and communities.

- Institute of Industrial and Systems Engineers: Professional society for industrial and systems engineers. Supports continuous improvement and Lean Six Sigma practitioners through training, communities and events.

- Association for Supply Chain Management: Supply chain association that supports continuous improvement and Lean practices across operations. Offers education, certifications and communities.

Industry-specific associations:

- Society of Manufacturing Engineers: Manufacturing professionals association. Supports Lean practitioners via the Lean Certification program (in partnership) and continuous improvement resources.

- Lean Construction Institute: Industry association advancing Lean methodologies in construction. Offers education, communities of practice and resources on reducing waste and variation.

Takeaway: Active participation in associations like ASQ, LEI and Shingo Institute provides essential networking, certification pathways and professional development opportunities that distinguish six sigma professionals in the marketplace.

Which events connect professionals with lean six sigma experience?

Professional conferences provide learning, networking and exposure to emerging practices that advance lean six sigma careers. Regular attendance keeps practitioners current with methodologies and connects them with industry leaders.

Premier Six Sigma conferences:

- ASQ Six Sigma Conference: ASQ’s dedicated Lean and Six Sigma event featuring DMAIC, Lean, continuous improvement and data-driven quality sessions for Green, Black and Master Black Belts across industries.

- ASQ World Conference on Quality and Improvement: ASQ’s flagship global quality conference with strong Lean Six Sigma, operational excellence and continuous improvement tracks.

Leading Lean events:

- AME Excellence Conferences: A premier lean-focused conference by AME featuring plant tours, practitioner case studies and sessions on lean transformation and Six Sigma.

- LEI Lean Summit: LEI’s national summit on lean management, improvement kata and enterprise transformation for continuous improvement and Lean Six Sigma practitioners.

- Shingo Conference: The Shingo Institute’s annual conference centered on the Shingo Model and operational excellence, drawing Lean and Six Sigma leaders worldwide.

Operational excellence and process improvement conferences:

- OPEX Week: A leading U.S. Operational Excellence summit uniting Lean Six Sigma, process excellence and transformation leaders across industries.

- Kata Summit: A focused event on scientific thinking, improvement kata and coaching kata that complements Lean Six Sigma problem-solving and culture change.

Industry-specific events:

- IISE Annual Conference: IISE’s primary conference with robust tracks on Lean, Six Sigma and operational excellence for industry and academia.

- IISE Healthcare Systems Process Improvement Conference: IISE’s healthcare-focused process improvement conference featuring lean, Six Sigma and data-driven improvement in clinical and operational settings.

- Lean Construction Institute Congress: The Lean Construction Institute’s premier event focusing on lean methods in construction, with applicability to Lean Six Sigma in project delivery.

Takeaway: Regular attendance at conferences like ASQ Six Sigma Conference, AME Excellence events and LEI Lean Summit provides essential professional development, networking opportunities and exposure to emerging practices and technologies.

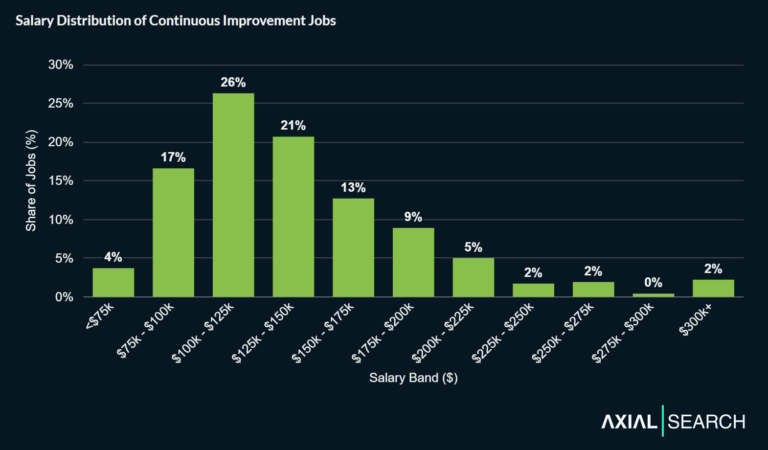

Six sigma job compensation insights

Lean six sigma compensation reflects the high value organizations place on process improvement expertise. Salaries vary significantly based on belt level, experience, industry and geographic location.

Compensation by certification level:

- Green Belt: US total pay Most Likely Range often around $108,000–$166,000, with median total pay around $130,000 reflecting base plus additional pay.

- Master Black Belt: Most Likely Range for total pay commonly around $134,000–$216,000 in the US, with median total pay around $170,000 (varies by location, company and additional pay).

Total compensation packages typically include base salary plus performance bonuses, profit sharing and other incentive pay. The spread between base and total compensation can reach 15–25% in many organizations, reflecting the direct business impact of successful improvement projects.

Geographic factors significantly influence compensation. Major metropolitan areas and regions with high concentrations of manufacturing or professional services typically offer premium salaries to reflect cost of living and competitive demand.

Industry variations are substantial. Technology, aerospace, pharmaceuticals and financial services generally provide higher compensation than government, nonprofit or smaller manufacturing organizations. Consulting firms often offer competitive packages to attract experienced practitioners.

Career progression delivers significant earning growth. Advancement from Green Belt to Black Belt can increase compensation by 30–40%. Master Black Belt and director-level roles command executive compensation reflecting strategic organizational impact.

Takeaway: Six sigma compensation ranges from $130,000 median for Green Belts to $170,000+ for Master Black Belts, with total compensation packages including bonuses and profit sharing that can increase earnings by 15–25% above base salary.

Final thoughts

Lean six sigma jobs represent critical roles in organizations committed to operational excellence and sustainable competitive advantage. As quality costs continue consuming 15–40% of revenue in many companies, skilled practitioners who can systematically eliminate waste and variation deliver measurable value that directly impacts the bottom line. Whether you’re transitioning from engineering, operations or quality roles, or starting fresh in this field, the combination of structured methodologies, statistical rigor and cross-functional leadership makes six sigma careers both financially rewarding and professionally fulfilling.