Impact of operational excellence jobs on business

Operational excellence professionals address a critical gap between strategic intent and execution capability. Cost of Quality can reach 15–20% of sales in many organizations through defects, scrap, rework, and warranty costs. OpEx efforts that systematically reduce these failures materially lower the cost of poor quality and improve margins.

The impact of these process optimization professionals goes beyond mere cost savings. Organizations also measure OpEx effectiveness across Safety, Quality, Delivery, and Morale. The Shingo Model’s Results dimension explicitly uses these categories to assess enterprise excellence, recognizing that sustainable performance requires balanced improvements across operational metrics.

Process efficiency improvements deliver compounding benefits. Value‑stream mapping captures process time, wait time, inventory, and information flow to quantify lead time and flow efficiency. The impact of operational excellence practitioners shows up as shorter lead times, reduced bottlenecks, and faster time-to-market—advantages that materially strengthen a company’s competitive position.

Takeaway: Operational excellence jobs drive measurable business value by systematically reducing waste, defects, and cycle time while improving safety, quality, and employee engagement across operations.

What are the main responsibilities in operational excellence jobs?

Operational excellence roles combine strategic planning with hands-on improvement execution. Responsibilities span process analysis, team facilitation, and systematic problem-solving across operations.

Core responsibilities include:

- Lean Six Sigma initiatives: Lead DMAIC projects to systematically remove waste and reduce process variation, coaching teams on methods and tools that improve operational performance.

- Value stream mapping: Map current and future state value streams to visualize material and information flow, identify waste, and design targeted improvements.

- Quality management systems: Establish and maintain QMS that documents processes, procedures, and responsibilities to meet customer and regulatory requirements and drive continual improvement.

- Kaizen facilitation: Facilitate ongoing continuous improvement and rapid improvement events to engage employees in eliminating waste and improving quality and flow.

- 5S implementation: Implement sort, set in order, shine, standardize, sustain to create a visual, safe, and efficient workplace that enables consistent performance.

- A3/PDCA problem solving: Coach structured problem solving to clarify problems, analyze root causes, test countermeasures, and standardize successful changes.

- CAPA leadership: Lead corrective and preventive action by investigating root causes of nonconformities, implementing corrective actions, and establishing preventive measures to avoid recurrence.

- Hoshin kanri: Align improvement priorities to strategy using policy deployment with catchball and regular reviews to ensure execution and course correction.

- Benchmarking: Benchmark processes and performance against best-in-class to identify gaps and adopt proven practices that improve efficiency and quality.

Takeaway: Operational excellence responsibilities center on leading structured improvement projects, facilitating team problem-solving, and building systems that embed continuous improvement into daily operations.

How are operational excellence roles structured within organizations?

Operational excellence capability typically spans multiple organizational structures depending on scope and maturity. The Shingo Model emphasizes that Enterprise Alignment and Results driven by principles and leadership indicate OpEx should be positioned close to senior leaders like COOs or business unit heads to align improvement with strategy.

The Baldrige Excellence Framework integrates Leadership, Strategy, Customers, Measurement, Workforce, Operations, and Results—Operational Excellence collaborates across all these areas to drive systemic performance and quality rather than operating in silos.

OpEx roles often lead through influence rather than direct authority. Black Belts are typically full-time project leaders who drive cross-functional improvements without formal line authority. Master Black Belts provide coaching and program oversight, while Champions are executives who sponsor initiatives and remove barriers.

Team structures emphasize cross-functional collaboration. Improvement teams intentionally include a senior leader sponsor, process leaders, a project manager, and staff who work in the process—illustrating that many Operational Excellence practitioners lead by influence rather than through direct reports.

Takeaway: Operational excellence roles span from specialist positions embedded in operations to enterprise-level program offices, with success depending on strong executive sponsorship and cross-functional collaboration rather than hierarchical authority.

Key skills for operational excellence careers

Operational excellence careers require analytical rigor combined with interpersonal capabilities to drive adoption and sustain improvements. Practitioners must master both technical methods and organizational change dynamics.

Foundational skills include:

- DMAIC methodology: Apply Define, Measure, Analyze, Improve, Control as a data-driven improvement cycle to reduce variation and defects and improve processes.

- Statistical process control: Use control charts to monitor process behavior over time and determine whether a process is in statistical control, enabling ongoing quality control and continuous improvement.

- Root cause analysis: Apply problem-solving methods like 5 Whys and cause-and-effect diagrams to identify underlying causes of issues and prevent recurrence.

- Value stream mapping: Visualize material and information flow using Lean tools to identify waste and design improved future states for better quality, lead time, and cost.

- Standardized work: Define the best-known method to perform tasks, stabilizing processes and creating a baseline for continuous improvement.

- Cost of Quality analysis: Categorize prevention, appraisal, and failure costs to quantify the financial impact of poor quality and the benefits of improvement.

- Process approach: Apply ISO 9001 principles including risk-based thinking and the Plan-Do-Check-Act cycle to improve organizational performance and customer satisfaction.

- Process frameworks: Use APQC’s Process Classification Framework as a common language for mapping, benchmarking, and managing processes across thousands of organizations.

- Change management: Apply structured change methods recognizing that projects with excellent change management are 7x more likely to meet or exceed objectives than those with poor change management.

Advanced capabilities address cultural transformation:

- Leadership for culture: Shape organizational culture to sustain operational excellence, because ideal results require ideal behaviors driven by principles and leadership systems.

- Team facilitation: ASQ’s CMQ/OE Body of Knowledge includes leadership, communication skills, and team dynamics as core competencies for managing quality and organizational excellence.

Takeaway: Success in operational excellence careers requires mastering technical methods like Six Sigma and Lean while developing strong facilitation, change management, and leadership capabilities to drive adoption and sustain results.

Which models or frameworks are used in operational excellence jobs?

Operational excellence practitioners apply proven frameworks to diagnose problems, design improvements, and sustain gains. Mastering multiple models enables selection of the right approach for each situation.

Essential frameworks include:

- Six Sigma: A disciplined, data-driven methodology that targets 3.4 defects per million opportunities by reducing process variation—improving quality and performance in critical operations.

- DMAIC: The structured, data-driven cycle (Define, Measure, Analyze, Improve, Control) for improving existing processes and sustaining gains—an OpEx staple for tackling recurring performance gaps.

- Toyota Production System: Focuses on eliminating waste and unevenness through Just-in-Time flow and Jidoka (built-in quality) to deliver high quality, low cost, and short lead times.

- Value stream mapping: Maps material and information flow from end-to-end to reveal bottlenecks and wastes, enabling design of a future-state process with improved flow and lead time.

- Plan-Do-Check-Act: Provides an iterative learning loop to pilot changes, measure results, and standardize improvements—foundational to daily continuous improvement in operations.

- Kaizen: Engages everyone in small, frequent improvements that compound over time—embedding problem-solving into daily work and building an OpEx culture.

- 5S: Sort, Set in order, Shine, Standardize, Sustain creates a visual, organized workplace that reduces waste, improves safety, and stabilizes processes for higher quality and throughput.

- Root cause analysis: Uses tools like the 5 Whys and cause-and-effect (Ishikawa) diagrams to identify and eliminate underlying causes rather than symptoms—critical for durable operational fixes.

- Baldrige Excellence Framework: Provides a systems framework across leadership, strategy, customers, measurement, workforce, operations, and results to align and elevate organizational performance.

- Shingo Model: Emphasizes principles like respect, scientific thinking, flow & pull, and systems that drive ideal behaviors—embedding culture as the engine of Operational Excellence.

Advanced frameworks address specific challenges:

- Statistical process control: Applies control charts to distinguish common-cause from special-cause variation, stabilize processes, and improve capability—key to sustaining OpEx gains.

- Design of experiments: Systematically varies inputs to uncover cause–effect relationships and optimize process settings with fewer trials—accelerating yield and quality improvements.

- Poka-yoke: Designs processes and devices that prevent or immediately detect errors, reducing defects and rework in operations.

- SCOR Model: Standardizes and measures supply chain processes across Plan, Source, Make, Deliver, Return, and Enable—supporting benchmarking and targeted OpEx improvements.

Takeaway: Proficiency across frameworks from Six Sigma and Lean to the Baldrige and Shingo models enables practitioners to select the right tools for each context and build sustainable operational excellence systems.

What software tools support operational excellence work?

Operational excellence professionals leverage specialized software to analyze processes, track improvements, and sustain gains. Tools span statistical analysis, process mapping, workflow automation, and continuous improvement management.

Statistical and analysis tools provide quantitative rigor:

- Minitab: Provides control charts, capability analysis, DOE, regression, and visualizations used to quantify variation and verify improvements in Operational Excellence projects.

- Minitab Workspace: Includes process maps, SIPOC, value stream mapping, fishbone diagrams, and FMEA to plan, analyze, and execute continuous improvement work.

- AnyLogic: Supports discrete-event, agent-based, and system dynamics simulation to test process changes, capacity scenarios, and throughput before implementation.

Process mapping and visualization tools enable analysis:

- Lucidchart: Supports value stream mapping, process flow diagrams, and collaboration to visualize waste and lead time across value streams.

- Microsoft Visio: Provides flowcharting, cross-functional process maps, and templates to document standard work and procedures.

Process mining and automation platforms:

- Celonis: Discovers as-is process flows from system event logs, highlights bottlenecks and rework, and quantifies improvement potential.

- Camunda: Executes BPMN workflows and DMN decisions to standardize and scale process automation across systems and teams.

Quality and improvement management systems:

- KaiNexus: Captures improvement ideas, manages Kaizen events, A3s, and projects, and tracks impact for OpEx programs.

- ETQ Reliance: Centralizes CAPA, audits, document control, and change management to drive quality and compliance improvements at scale.

- InfinityQS ProFicient: Delivers real-time SPC, control charts, and analytics to reduce variation and scrap across production processes.

Standard work and training platforms:

- Dozuki: Enables creation, control, and distribution of standard work instructions and training to improve consistency and reduce defects.

Takeaway: Effective operational excellence requires proficiency across statistical software like Minitab, process mapping tools like Lucidchart, process mining platforms like Celonis, and improvement management systems like KaiNexus to analyze, execute, and sustain improvements.

Qualifications for operational excellence manager jobs

Operational excellence roles typically require bachelor’s degrees in engineering, business, operations management, or related fields. Industrial production managers typically need a bachelor’s degree, with some employers preferring candidates with graduate degrees like MBAs.

Quality Control Systems Managers most commonly require a four-year bachelor’s degree, reflecting the technical and managerial demands of these positions.

Professional experience often carries more weight than specific educational credentials. Employers value demonstrated success leading improvement projects, statistical analysis capabilities, and understanding of manufacturing or service operations. Many practitioners transition from quality engineering, industrial engineering, or production management.

Industry-specific knowledge can be advantageous. Healthcare organizations prefer candidates familiar with clinical workflows and regulatory compliance. Manufacturing values understanding of production systems and supply chain dynamics. Financial services seeks practitioners experienced with process standardization and risk management.

Technical skills complement formal education. Proficiency with statistical software, process mapping tools, and improvement methodologies distinguishes strong candidates. Project management capabilities and change leadership experience enhance effectiveness in driving adoption.

Takeaway: Operational excellence careers require bachelor’s degrees in engineering, business, or related fields, with professional experience in process improvement, statistical analysis, and project leadership often valued more highly than specific academic credentials.

What certifications benefit operational excellence careers?

Professional certifications demonstrate expertise and commitment to operational excellence best practices. Several organizations offer respected credentials that enhance career prospects and earning potential.

Leading certifications include:

- ASQ Certified Manager of Quality/Organizational Excellence: Signals capability to lead and align quality and operational excellence across the enterprise, covering strategy deployment, change leadership, and performance measurement.

- ASQ Certified Master Black Belt: Demonstrates mastery in mentoring Black Belts, leading deployments, and advanced statistical/Lean methods; candidates must hold ASQ CSSBB (or equivalent) and meet experience/portfolio requirements.

- APICS CPIM: Establishes mastery of planning, MRP, scheduling, and S&OP—core levers for operational efficiency and throughput; widely recognized for manufacturing and supply operations.

- PMP Certification: Global standard for leading projects, useful for delivering OpEx initiatives on time and budget; requires documented experience and passing a rigorous exam.

- SME/AME/Shingo Lean Certifications: Competency-based Lean certifications that evidence applied continuous-improvement capability via exams and portfolios; jointly endorsed by SME, AME, and The Shingo Institute.

Specialized certifications address specific contexts:

- ABPMP CBPP: Certifies professional competence in process modeling, analysis, improvement, and governance per the BPM CBOK—directly aligned to systematic operational optimization.

- ITIL 4 Foundation: Introduces service value systems and practices (e.g., incident, problem, change) to improve service operations—relevant for OpEx in service and IT-enabled processes.

Takeaway: Professional certifications like ASQ’s CMQ/OE and Master Black Belt, APICS CPIM, and PMP enhance credibility and career advancement, with specialized credentials available for specific methodologies or industry contexts.

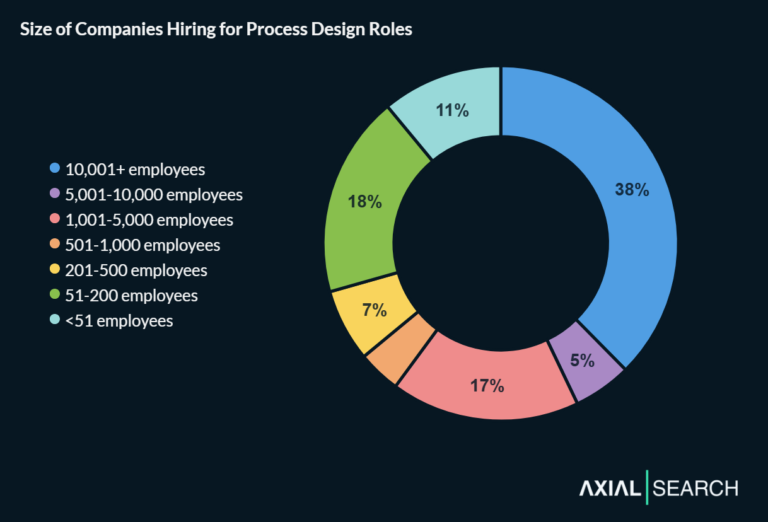

Advancement paths in operational excellence jobs

Operational excellence offers diverse career paths with opportunities to progress from specialist roles to enterprise leadership positions. Progression typically follows increased scope, complexity, and strategic responsibility.

Common career progression includes:

- Operational Excellence Specialist/Analyst: Entry-level roles supporting improvement projects and data analysis

- Operational Excellence Engineer/Coordinator: Mid-level positions leading specific initiatives or workstreams

- Operational Excellence Manager: Experienced practitioners managing multiple projects or functional improvements

- Senior Manager/Director of Operational Excellence: Leadership roles overseeing enterprise programs and building capability

- VP of Operational Excellence/Chief Operating Officer: Executive positions setting transformation strategy and organizational direction

Entry points vary across industries and backgrounds. Lean Six Sigma is a structured method used across industries, with many operational excellence careers starting by gaining LSS training and belts and applying project work to build experience.

Industrial engineers typically need a bachelor’s degree and design efficient systems that integrate workers, machines, materials, and information—core Operational Excellence capabilities that provide natural career pathways.

Industrial production managers generally have bachelor’s degrees and related production work experience, implementing continuous improvement best practices to impact efficiency and quality—common responsibilities that align with Operational Excellence progression.

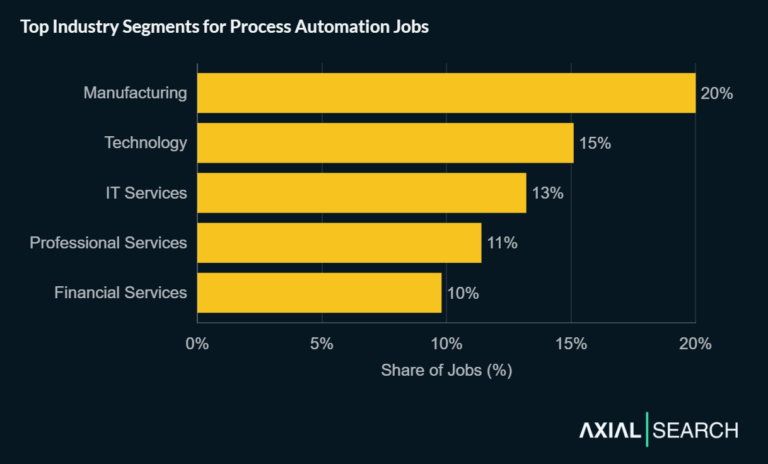

Industry demand remains strong across sectors. Manufacturing is the largest employer of industrial engineers, with substantial roles in transportation equipment, computer and electronic products, and machinery—indicating strong Operational Excellence demand. A significant share of industrial engineers work in professional, scientific, and technical services, reflecting opportunities in technology, engineering services, and consulting.

Specialized sectors offer unique opportunities. The Joint Commission’s Robust Process Improvement program blends Lean Six Sigma and change management across healthcare organizations to improve safety and quality, signaling strong OpEx adoption in healthcare.

ISPE’s Operational Excellence Community of Practice focuses on eliminating waste and improving performance in pharmaceutical manufacturing, underscoring continued OpEx opportunities in life sciences.

Takeaway: Operational excellence careers offer multiple advancement paths from specialist to executive roles, with strong demand across manufacturing, healthcare, professional services, and technology sectors for practitioners who combine technical methods with strategic leadership.

Which professional associations support operational excellence roles?

Professional associations provide networking, education, and resources that accelerate career development in operational excellence. Active membership demonstrates commitment and provides access to best practices and peer communities.

Primary operational excellence associations include:

- American Society for Quality (ASQ): Global community of quality and continuous improvement professionals offering certifications (e.g., Six Sigma), standards, and best practices central to Operational Excellence.

- The Shingo Institute: Home of the Shingo Model and Shingo Prize; advances cultural and operational excellence principles that drive sustainable performance improvements.

- OPEX Society: Global community dedicated to operational excellence, continuous improvement, and transformation, offering articles, webinars, and practitioner networking.

- Lean Enterprise Institute: Nonprofit founded by James P. Womack advancing lean thinking and practice; provides learning resources, events, and a practitioner network for process optimization.

- Association for Manufacturing Excellence (AME): Nonprofit focused on enterprise excellence and lean; provides practitioner communities, events, and resources for continuous improvement and operational performance.

Related professional organizations offer valuable resources:

- APQC: Membership-based research and benchmarking organization known for process and performance management, including the Process Classification Framework used in OPEX.

- ABPMP: Professional association advancing BPM practice, certifications (CBPA, CBPP), and process governance foundational to OPEX.

- Institute of Industrial and Systems Engineers (IISE): Professional society for industrial and systems engineering with strong focus on lean, Six Sigma, and process optimization relevant to operational excellence roles.

- Baldrige Performance Excellence Program: U.S. national program offering the Baldrige Excellence Framework and Criteria for Performance Excellence used to assess and guide organizational operations and results.

Takeaway: Active participation in associations like ASQ, The Shingo Institute, and OPEX Society provides essential networking, certification pathways, and access to best practices that distinguish operational excellence professionals.

What events and conferences help operational excellence professionals?

Professional conferences provide learning, networking, and exposure to emerging practices that advance operational excellence careers. Regular attendance demonstrates commitment to professional development and provides access to practitioner case studies and thought leadership.

Premier operational excellence events include:

- Shingo Conference: Global conference centered on the Shingo Model for operational excellence, featuring award recipients and deep dives on culture, systems, and results.

- ASQ World Conference on Quality and Improvement (WCQI): ASQ’s flagship annual conference covering quality, continuous improvement, Lean Six Sigma, and operational excellence across industries.

- AME Annual Conference: Association for Manufacturing Excellence’s premier event focused on lean, continuous improvement, and enterprise excellence with practitioner case studies and tours.

- OPEX Week: IQPC’s flagship gathering of operational excellence and transformation leaders covering strategy execution, process optimization, and automation.

- BTOES Insights: Cross-industry summit spotlighting enterprise operational excellence, Lean Six Sigma, and transformation leadership with practitioner-led sessions.

Specialized conferences address specific methodologies and technologies:

- ASQ Lean and Six Sigma Conference: ASQ’s specialty conference focused on Lean, Six Sigma, and continuous improvement methods to drive quality, cost, and performance outcomes.

- IISE Annual Conference: Institute of Industrial and Systems Engineers’ annual event on industrial engineering, process optimization, and operations research for OpEx practitioners.

- Celosphere: Celonis’ annual conference on process mining and execution management showcasing data-driven operational excellence in practice.

Takeaway: Regular attendance at conferences like the Shingo Conference, ASQ WCQI, and AME Annual provides essential professional development, networking opportunities, and exposure to emerging operational excellence practices and technologies.

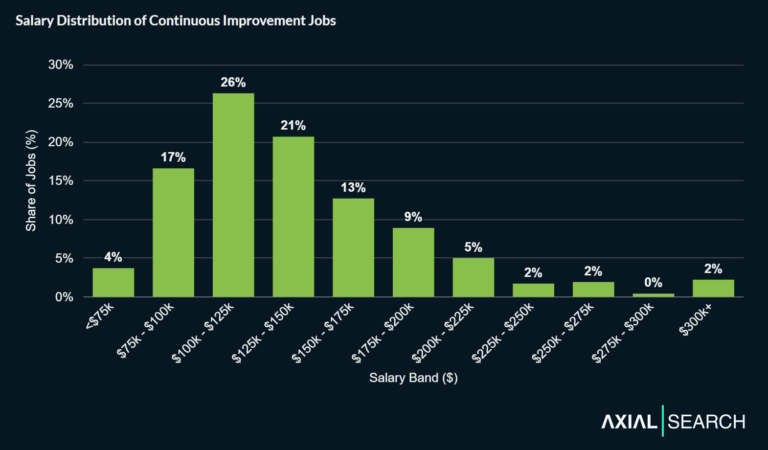

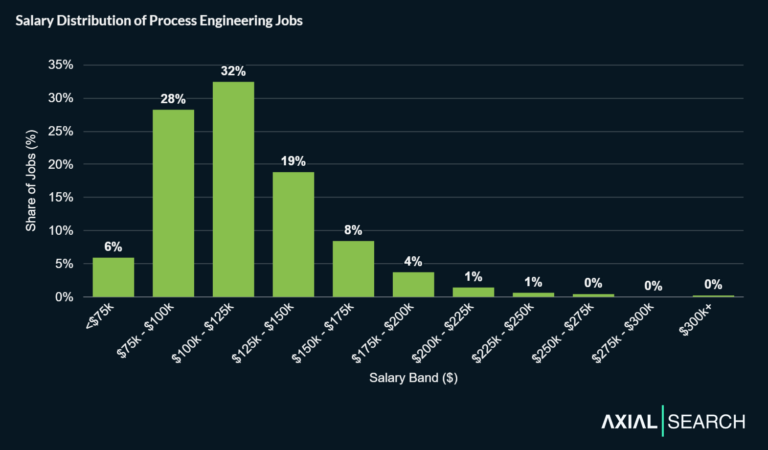

Salary data for operational excellence jobs

Operational excellence compensation varies based on experience level, geographic location, industry, and organizational scope. Salaries reflect the strategic value these roles deliver through measurable operational improvements.

Compensation by experience level:

- Operational Excellence Specialist: Total pay range: $77K – $127K/yr, Median total pay: $98K/yr

- Operational Excellence Engineer: Total pay range: $102K – $160K/yr, Median total pay: $127K/yr

- Operational Excellence Manager: Total pay range: $112K – $190K/yr, Median total pay: $145K/yr

- Director of Operational Excellence: Total pay range: $142K – $240K/yr, Median total pay: $183K/yr

Total compensation typically includes base salary plus performance bonuses, profit sharing, and other incentives. Organizations often tie bonuses to achievement of specific operational metrics like quality improvement, cycle time reduction, or cost savings.

Geographic and industry factors significantly impact compensation. Major metropolitan areas and technology hubs typically offer higher salaries. Manufacturing, pharmaceuticals, and technology sectors generally provide premium compensation compared to non-profit or government organizations.

Certification and advanced degrees enhance earning potential. Practitioners with multiple certifications like ASQ Master Black Belt, CPIM, or PMP typically command higher compensation. Advanced degrees in industrial engineering, operations management, or business administration often correlate with faster career progression and higher salaries.

Takeaway: Operational excellence salaries range from upper-$90Ks for specialist roles to $240K+ for director positions, with total compensation including performance bonuses tied to measurable operational improvements and cost savings.

Final thoughts

Operational excellence jobs represent critical roles in today’s competitive business environment. Organizations need practitioners who can systematically improve quality, reduce waste, and accelerate flow while building cultures of continuous improvement. With strong demand across manufacturing, healthcare, technology, and services, these careers offer both intellectual challenge and measurable business impact for professionals who combine analytical rigor with change leadership capabilities.