Purpose of process improvement jobs in organizations

Process improvement professionals solve a critical business challenge: translating operational inefficiency into competitive advantage.

The value of these process optimization leaders can present in many ways. Organizations measure success using SCOR performance attributes—reliability metrics like on-time delivery, responsiveness indicators such as cycle times, agility measures, cost reductions, and asset management efficiency. Process improvers align their work to lift overall value delivery across these categories.

Financial validation matters. Practitioners should establish a benefits register with specific targets for cost savings, cost avoidance, revenue uplift, risk mitigation, and customer outcomes. They can then track benefit realization over time and validate results with Finance teams to substantiate their contribution.

Process mining KPIs provide concrete evidence of value creation. Practitioners quantify improvements through metrics like reduced throughput time, higher on-time delivery rates, lower rework percentages, fewer process variants, and improved conformance to standards. These measurements prove which bottlenecks were removed and what level of standardization was achieved.

Takeaway: Process improvement jobs transform operational waste into measurable business value through structured methodologies that reduce costs, accelerate cycle times, and validate financial impact with Finance partners.

What are the core responsibilities in process improvement jobs?

Process improvement professionals execute a disciplined sequence of activities to diagnose problems, implement solutions, and sustain results. Their responsibilities span the entire improvement lifecycle.

Problem definition and scoping set the foundation:

- Project Charter Development: Define the problem, identify customers, establish goals, and clarify project scope using SIPOC diagrams to focus improvement efforts on high-impact areas.

- Voice of Customer Analysis: Gather customer insights through surveys, interviews, and observation to translate VOC into critical-to-quality requirements that guide process changes.

Process analysis reveals improvement opportunities:

- Value Stream Mapping: Create visual maps of material and information flow to reveal waste and design more efficient future states.

- Root Cause Analysis: Use structured methods like 5 Whys and cause-and-effect diagrams to identify and verify the true causes of defects, delays, or waste.

- Data Collection and Validation: Collect process data and validate the measurement system to establish a reliable baseline for comparison.

- Pareto Analysis: Focus on the small number of causes that drive most problems or costs.

Solution development and implementation drive change:

- Countermeasure Development: Eliminate root causes by developing countermeasures, piloting solutions, and refining them before wider rollout.

- Kaizen Event Leadership: Lead rapid improvement events with cross-functional teams to quickly improve targeted processes and remove waste.

- Standardized Work Creation: Capture the best-known method as the basis for training, consistency, and further improvement.

- Risk Assessment: Use Failure Modes and Effects Analysis to anticipate potential failures, prioritize risks, and design mitigations before implementation.

Control and sustainment maintain improvements:

- Process Monitoring: Use control charts and other process controls to monitor stability, detect drift, and maintain improved performance over time.

- Visual Management Implementation: Implement visual management so status and abnormalities are visible at the point of work, enabling daily problem solving.

- PDCA Application: Apply the Plan–Do–Check–Act cycle for structured experimentation, learning, and control of process changes.

- Financial Impact Measurement: Measure the financial effects of improvements using cost-of-quality concepts to target and track reductions in the cost of poor quality.

Capability building ensures long-term success:

- Continuous Improvement Culture Development: Develop frontline and leader problem-solving capabilities and daily management routines to sustain continuous improvement.

Takeaway: Core responsibilities span from structured problem definition and data-driven analysis to solution implementation and control systems that sustain improvements, with success measured through validated financial impact and process KPIs.

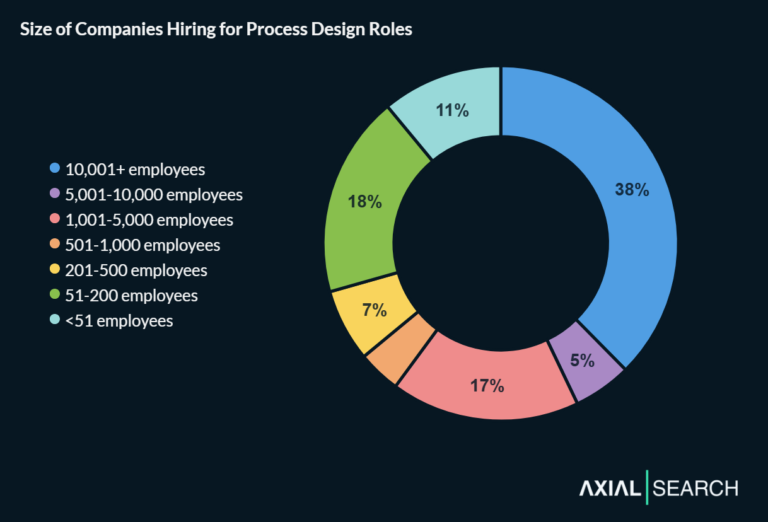

How are process improvement jobs structured within companies?

Process improvement professionals operate across diverse organizational structures, with placement and scope varying by company maturity and transformation scale.

Individual contributors and project leaders often work as Black Belts who influence without direct authority, leading DMAIC projects across functions. Program leads like Master Black Belts or Operational Excellence managers may oversee a small central team or Center of Excellence that builds capability enterprise-wide.

Cross-functional collaboration defines the work model. Effective improvement teams intentionally combine leadership, subject-matter expertise, and technical skills to represent all parts of the process impacted by change. This ensures solutions address real constraints and gain stakeholder buy-in.

Operations and production partnerships form the backbone of execution. Process improvement professionals work closely with operations leaders to develop and implement process changes, establish quality controls, and optimize workflow improvements. These relationships determine whether changes stick or fade.

Takeaway: Process improvement roles range from individual contributor Black Belts who lead projects through influence to program managers who oversee Centers of Excellence, with success depending on strong cross-functional partnerships with operations and production leaders.

Key skills for process improvement careers

Process improvement careers demand a distinctive blend of analytical rigor, structured methodology expertise, and collaborative leadership that bridges data and human systems.

Core analytical and methodological skills include:

- Lean Six Sigma: Fact-based, data-driven methodology combining Lean waste reduction with Six Sigma variation reduction to improve process performance and eliminate inefficiency.

- DMAIC: Disciplined roadmap to improve existing processes through Define, Measure, Analyze, Improve, and Control phases that deliver measurable results.

- Statistical Process Control: Statistical methods including control charts to monitor and control processes, establish baselines, detect special-cause variation, and sustain gains.

- Root Cause Analysis: Systematic techniques like 5 Whys and fishbone diagrams to identify underlying causes and prevent recurrence through effective, lasting fixes.

- Value Stream Mapping: Visual representation of end-to-end material and information flow to expose waste and prioritize improvements across the process.

- PDCA Cycle: Iterative testing and learning method to drive continuous improvement and evolve better processes over time.

Digital and automation competencies are increasingly critical:

- Process Mining: Event log analysis to discover, monitor, and improve real processes by interpreting process maps and conformance insights that pinpoint bottlenecks and compliance issues.

- Hyperautomation: Disciplined approach to rapidly identify, vet, and automate business and IT processes using RPA, process mining, and integration platforms.

- Generative AI Literacy: Understanding of how AI can automate or augment activities to unlock significant productivity potential, requiring collaboration with data and AI teams for process optimization.

Supporting competencies round out the skill set:

- BPMN 2.0: Standardized notation for modeling business processes to create shared, precise understanding among business and IT stakeholders when documenting and redesigning workflows.

- Project Management: Knowledge, skills, tools, and techniques to meet project requirements by planning, executing, and controlling process improvement initiatives on time and budget.

- Change Management: Clear communication, stakeholder engagement, and adoption planning skills, as projects with excellent change management are 7x more likely to meet or exceed objectives.

Takeaway: Success requires mastering traditional Lean Six Sigma methods while developing emerging capabilities in process mining, hyperautomation, and AI literacy to meet evolving demands for data-driven, technology-enabled process improvement.

Which frameworks are essential in process improvement careers?

Process improvement frameworks provide structured approaches to diagnose challenges, design interventions, and sustain results. Mastering multiple models allows practitioners to select the right tool for each situation.

Foundational improvement methodologies include:

- DMAIC: Structured, data-driven method to improve existing processes through Define, Measure, Analyze, Improve, and Control, reducing defects and variation to boost quality and cost-effectiveness.

- Value Stream Mapping: Maps material and information flow end-to-end to visualize delays, waste, and bottlenecks, prioritizing improvements that increase flow and customer value.

- Kaizen: Mindset and practice of small, frequent improvements driven by those who do the work, compounding gains in quality, speed, and cost.

- Root Cause Analysis: Set of methods to systematically trace symptoms to underlying causes and prevent recurrence, enabling durable fixes rather than quick patches.

Planning and scoping tools establish project foundations:

- SIPOC: High-level process scoping tool that clarifies boundaries, stakeholders, and deliverables, preventing scope creep and aligning improvement teams on what matters.

- A3 Report: Concise, visual method to define the problem, analyze root causes, propose countermeasures, and track follow-up, building shared understanding and accountability.

- Voice of the Customer: Translates customer needs into measurable CTQs so process changes target value, not just internal efficiency.

Advanced frameworks address specific challenges:

- Hoshin Kanri: Aligns improvement projects with strategic objectives through catchball and breakthrough targets, ensuring daily work advances enterprise goals.

- Theory of Constraints: Improves system throughput by identifying the constraint, exploiting it, subordinating other work to it, elevating it, and repeating the cycle, ensuring effort targets the true bottleneck.

- Service Blueprinting: Maps frontstage and backstage activities, customer actions, and support processes to surface failure points and improve service quality and cycle time.

Risk and quality control frameworks ensure robust solutions:

- FMEA: Proactively identifies how a process can fail, assesses severity, occurrence and detection, and prioritizes mitigations, reducing risk and rework costs.

- Statistical Process Control: Uses control charts to distinguish common-cause from special-cause variation so teams stabilize processes, cut defects, and avoid overcorrection.

- APQC Process Classification Framework: Common process taxonomy to benchmark and standardize processes, accelerating identification of improvement opportunities across functions.

Takeaway: Proficiency across multiple frameworks—from foundational DMAIC and VSM to specialized tools like Hoshin Kanri and Theory of Constraints—enables practitioners to diagnose process challenges accurately and design targeted, sustainable interventions.

What software tools support process improvement specialist jobs?

Process improvement professionals leverage diverse software categories to discover inefficiencies, model changes, automate workflows, and measure impact.

Process mining and discovery platforms reveal the truth:

- Celonis: Mines event logs to discover as-is processes, identify bottlenecks and conformance gaps, and drive optimization with its Execution Management capabilities.

- ARIS Process Mining: Provides discovery, conformance checking, and root-cause analysis to find and fix process inefficiencies.

Process modeling and orchestration tools design solutions:

- IBM Blueworks Live: Cloud-based tool to document, analyze, and collaborate on business processes using BPMN modeling.

- Camunda: BPMN- and DMN-based process orchestration platform to model and automate complex, end-to-end business processes across systems.

- Appian: Low-code platform that models, orchestrates, and monitors workflows and processes to accelerate improvement and automation.

Simulation software tests changes before implementation:

- AnyLogic: Supports business process simulation with discrete-event modeling to test process changes, capacities, and scenarios before implementation.

- Arena Simulation: Models, analyzes, and optimizes complex processes, enabling experimentation and improvement before changes go live.

Robotic Process Automation platforms execute improvements:

- UiPath: Enterprise automation platform that builds, manages, and runs software robots to automate repetitive process steps end-to-end.

- Automation 360: Cloud-native RPA platform to automate tasks and workflows across applications and systems.

Statistical analysis tools validate results:

- Minitab: Provides control charts, capability analysis, DOE, and other statistical tools used in Lean Six Sigma and process improvement.

Continuous improvement management platforms coordinate efforts:

- KaiNexus: Captures improvement ideas, manages Kaizen and A3 events, and tracks outcomes and impact across continuous improvement programs.

Takeaway: Effective process improvement requires proficiency across process mining platforms like Celonis, modeling tools like Blueworks and Camunda, RPA solutions like UiPath, and statistical software like Minitab to discover, design, automate, and validate improvements.

Education requirements for process improvement careers

Process improvement roles welcome diverse educational backgrounds, with employers valuing relevant degrees combined with hands-on experience in analytical problem-solving and process optimization.

Industrial Engineers—whose work centers on improving processes and systems—typically need a bachelor’s degree in industrial engineering or a related engineering field. This technical foundation provides strong analytical and systems-thinking capabilities.

Management analyst roles typically require a bachelor’s degree, though some employers prefer candidates with a master’s degree, often an MBA. These roles focus on recommending ways to improve organizational efficiency through process analysis.

Common undergraduate majors include industrial engineering, mechanical engineering, business administration, operations management, supply chain management, and applied mathematics. Graduate degrees in business administration, operations research, or organizational development can accelerate career progression.

Industry-specific knowledge adds value. Manufacturing environments benefit from engineering backgrounds. Healthcare settings value clinical or health administration knowledge. Financial services seek understanding of regulatory and compliance requirements.

Practical experience often matters more than specific degrees. Demonstrated project leadership, data analysis capabilities, and understanding of operational dynamics prove competency regardless of educational pedigree.

Takeaway: Process improvement careers typically require bachelor’s degrees in engineering, business, or related fields, with many practitioners holding advanced degrees like MBAs, though demonstrated analytical skills and process optimization experience often prove more valuable than specific educational credentials.

Which certifications are valuable for process improvement jobs?

Professional certifications demonstrate expertise and commitment to process improvement best practices. Several organizations offer respected credentials that enhance career prospects and validate competency.

Six Sigma certifications form the cornerstone:

- Certified Six Sigma Green Belt: Validates ability to apply Six Sigma DMAIC and basic quality tools to analyze and solve process problems; CSSGBs lead or support improvement projects under Black Belt guidance.

- Certified Six Sigma Black Belt: Demonstrates mastery of Six Sigma philosophies and principles, team leadership, and advanced analytical tools to lead DMAIC projects that reduce variation and improve performance.

Foundational quality certifications include:

- Quality Improvement Associate: Entry-level credential covering foundational quality tools and improvement methods for contributing to and supporting process improvement teams.

- Certified Quality Engineer: Validates competence in product and process quality evaluation and control, including statistical methods, metrology, and quality management systems to improve processes.

- Certified Manager of Quality: Recognizes leaders who champion process improvement initiatives, align quality systems with organizational strategy, and drive change to improve performance and customer satisfaction.

Lean-focused certifications build practical skills:

- Lean Bronze Certification: Industry-recognized program co-developed by SME, AME, and The Shingo Institute; Bronze level focuses on tactical application of lean methods to implement continuous improvement.

Business process management credentials address workflow optimization:

- Certified Business Process Professional: Certifies experienced BPM practitioners against the ABPMP BPM CBOK, covering process analysis, design, modeling, improvement, governance, and transformation.

Specialized certifications address specific methodologies:

- Theory of Constraints Certification: Globally recognized certifications covering bottleneck management, throughput improvement, CCPM, and supply chain for systemic process improvement.

- ISO 9001 Lead Auditor: Certifies ability to plan, conduct, and lead audits of quality management systems against ISO 9001 requirements and ISO 19011 auditing guidelines to drive continual improvement.

- ITIL 4 Foundation: Introduces the ITIL service value system, guiding principles, and practices to improve IT-enabled service processes and co-create business value.

Takeaway: Six Sigma Green Belt and Black Belt certifications provide the most widely recognized credentials, supplemented by specialized certifications in Lean, BPM, Theory of Constraints, and quality management that address specific improvement contexts and methodologies.

Advancement opportunities in process improvement jobs

Process improvement offers diverse career paths with opportunities to specialize by industry, methodology, or organizational scope. Progression typically follows increased complexity, strategic impact, and leadership responsibility.

Typical career progression includes:

- Process Improvement Analyst/Coordinator: Entry-level roles supporting data collection, analysis, and project coordination

- Process Improvement Specialist/Consultant: Mid-level practitioners leading specific improvement projects or workstreams

- Senior Process Improvement Specialist: Experienced professionals managing complex, cross-functional initiatives

- Process Improvement Manager/Director: Leadership roles overseeing programs, building capability, and aligning improvement with strategy

- VP of Operational Excellence/Chief Process Officer: Executive positions leading enterprise-wide transformation and continuous improvement culture

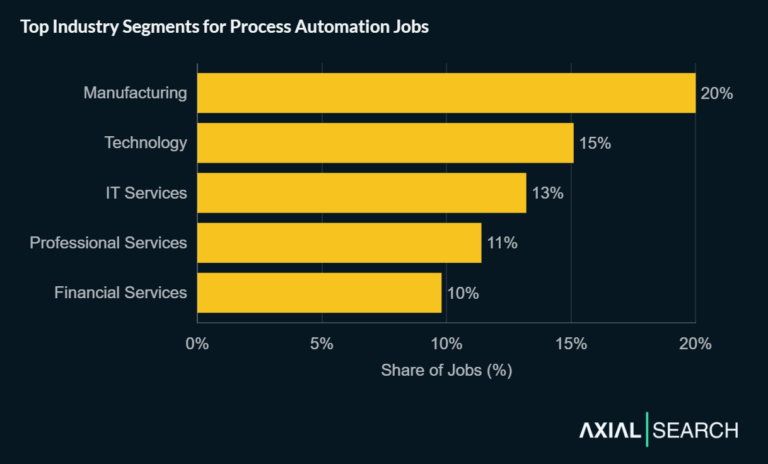

Common entry points span multiple functions. Management analysts—who drive organizational process improvement—commonly work in professional and technical services, federal and state government, company management, and finance and insurance sectors.

Alternative career paths leverage transferable skills. Industrial Engineers may use titles like Process Engineer, Manufacturing Engineer, Quality Engineer, Operations Engineer, and Production Engineer. Business Analysts pivot into improvement roles from positions like Business Process Consultant, Management Analyst, Program Analyst, and Business Systems Analyst.

Management consulting represents a common progression route. Management analysts typically need bachelor’s degrees and often industry experience, with some firms preferring master’s degrees. Analysts recommend efficiency improvements, providing valuable exposure to diverse challenges.

Industry specialization creates advancement opportunities. Healthcare demands expertise in clinical workflows and regulatory compliance. Manufacturing values deep knowledge of production systems. Financial services seeks understanding of risk management and compliance frameworks.

Takeaway: Process improvement careers offer multiple entry points through related fields like industrial engineering, business analysis, and management consulting, with progression opportunities spanning from specialist roles to executive operational excellence leadership positions across diverse industries.

Which associations support process improvement professionals?

Professional associations provide networking, education, and credibility that accelerate career development in process improvement.

Quality and continuous improvement associations include:

- American Society for Quality: Global community for quality and continuous improvement, offering certifications, training, and resources aligned to Lean and Six Sigma.

- International Society of Six Sigma Professionals: Global professional association dedicated to Six Sigma and process improvement practitioners with resources, community, and learning.

Lean-focused organizations provide specialized support:

- Lean Enterprise Institute: Nonprofit founded by Lean pioneers providing Lean thinking education, research, and a practitioner community focused on continuous improvement.

- Association for Manufacturing Excellence: Practitioner-to-practitioner network focused on lean and continuous improvement with events, tours, and learning for operational excellence.

- Society of Manufacturing Engineers: Professional association advancing manufacturing with communities and credentials supporting lean and continuous improvement practice.

Process management associations offer broader perspectives:

- Association of Business Process Management Professionals: Association for BPM professionals offering standards, the BPM CBOK, and certifications aligned to process improvement roles.

- APQC: Nonprofit leader in benchmarking and process management; steward of the Process Classification Framework and communities for process improvement.

Industrial engineering societies provide technical foundations:

- Institute of Industrial and Systems Engineers: Professional society advancing operational excellence and Lean Six Sigma across industries with education, chapters, and knowledge resources.

Takeaway: Active participation in associations like ASQ, ABPMP, and LEI provides essential networking, certification pathways, and professional development opportunities that distinguish process improvement professionals and accelerate career advancement.

What industry events benefit process improvement careers?

Professional conferences provide learning, networking, and exposure to emerging trends that advance process improvement careers and keep practitioners current with evolving methodologies.

Premier quality and continuous improvement events include:

- ASQ World Conference on Quality and Improvement: ASQ’s flagship annual event covering quality, Lean Six Sigma, and continuous improvement across industries.

- AME Annual Conference: Leading conference on lean, continuous improvement, and enterprise excellence with practitioner case studies and tours.

- Shingo Conference: Focuses on the Shingo Model and principles of operational excellence to sustain continuous improvement and cultural transformation.

- NIST Quest for Excellence Conference: Features Baldrige Award recipients sharing performance excellence and process improvement practices.

Process management and transformation events offer broader perspectives:

- APQC Process & Knowledge Management Conference: Brings together process and knowledge management leaders to share best practices in process improvement, benchmarking, and performance.

- Building Business Capability Conference: Covers business analysis, business architecture, and business process management to drive enterprise change and improvement.

- Business Transformation & Operational Excellence Summit: Global summit on operational excellence, process improvement, and end-to-end transformation programs.

- Process Excellence Network Events: Large-scale gathering for operational excellence, process improvement, and transformation leaders across sectors.

Technology-enabled improvement conferences showcase digital tools:

- Celosphere: Process mining and execution management conference showcasing data-driven process improvement at scale.

Industry-specific events provide context-relevant insights:

- IISE Healthcare Systems Process Improvement Conference: Dedicated to healthcare Lean, Six Sigma, and process improvement methods to enhance quality, safety, and efficiency.

- IISE Annual Conference: Industrial and systems engineering flagship conference featuring Lean, Six Sigma, and process improvement research and practice.

Takeaway: Regular attendance at conferences like ASQ WCQI, AME Annual, and Shingo Conference provides essential professional development, networking opportunities, and exposure to emerging process improvement methodologies and technologies across industries.

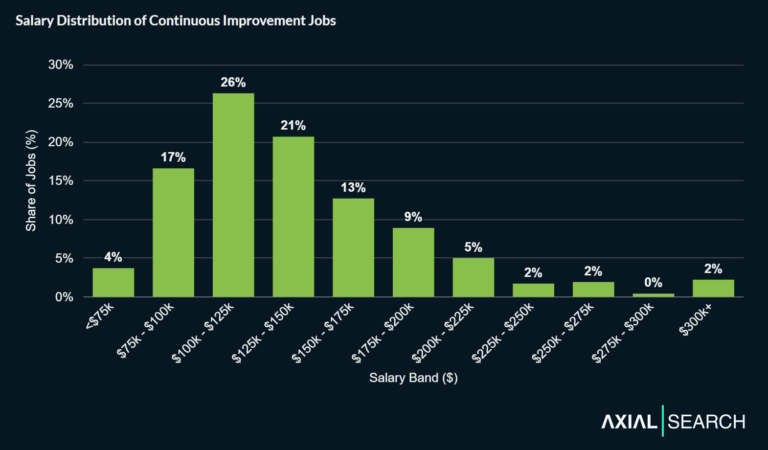

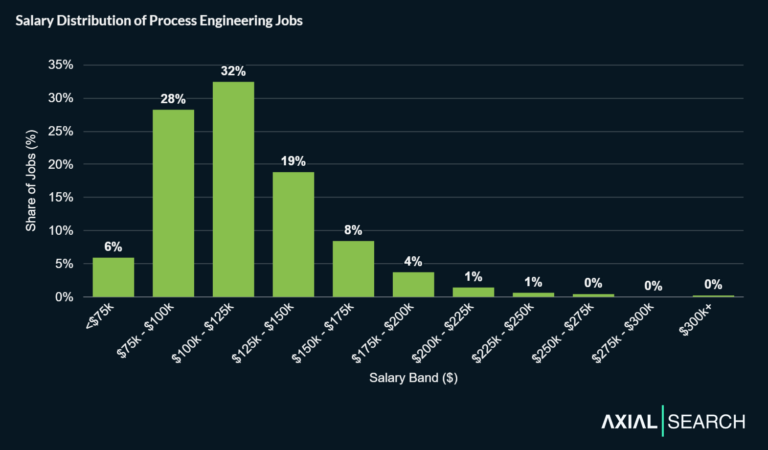

Salary outlook for process improvement jobs

Process improvement compensation varies significantly based on experience level, geographic location, industry, and organizational scope, with practitioners commanding premium salaries for their ability to drive measurable business value.

Compensation ranges by experience level include:

- Process Improvement Specialist: Total pay range of $76K – $125K/yr with median total pay of $97K/yr for mid-level professionals managing specific improvement projects.

- Process Improvement Consultant: Total pay range of $93K – $160K/yr with median total pay of $121K/yr for experienced practitioners leading cross-functional initiatives.

- Process Improvement Manager: Total pay range of $95K – $162K/yr with median total pay of $123K/yr for leadership roles overseeing programs and building organizational capability.

Total compensation extends beyond base salary. Additional pay typically includes cash bonuses tied to project results, profit sharing aligned with cost savings delivered, and performance incentives based on measurable improvements achieved.

Geographic factors significantly impact compensation. Major metropolitan areas and tech hubs offer 20-30% premiums over national averages to reflect cost of living. California, New York, and Washington typically lead in compensation levels.

Industry variation affects earning potential. Technology, financial services, and consulting generally provide premium compensation. Manufacturing and healthcare offer competitive salaries with strong benefits. Government and nonprofit sectors typically pay below private-sector averages but offer better work-life balance.

Certification and specialization increase earning power. Six Sigma Black Belts command higher salaries than Green Belts. Process mining expertise and automation skills currently carry market premiums reflecting high demand and limited supply.

Takeaway: Process improvement salaries span from mid-$70Ks for specialist roles to $160K+ for management positions, with total compensation including bonuses and profit sharing that can increase earnings by 20-40% above base salary based on measurable improvements delivered.

Final thoughts

Process improvement jobs represent a high-impact career path for analytical professionals who want to drive measurable business value. As organizations face mounting pressure to reduce costs, accelerate cycles, and compete through operational excellence, skilled practitioners who can diagnose inefficiencies and implement sustainable solutions will remain in strong demand. Whether you enter through industrial engineering, business analysis, or quality management, the combination of structured methodologies, digital tools, and cross-functional leadership makes process improvement a career that delivers both professional growth and tangible organizational impact.